NUCLEAR

NUCLEAR Welding

AMET has designed and manufactured turn-key nuclear welding solutions for Nuclear Applications since 1989. With an emphasis on precision fixturing and controls, we produce some of the most automated systems for Nuclear welding applications.

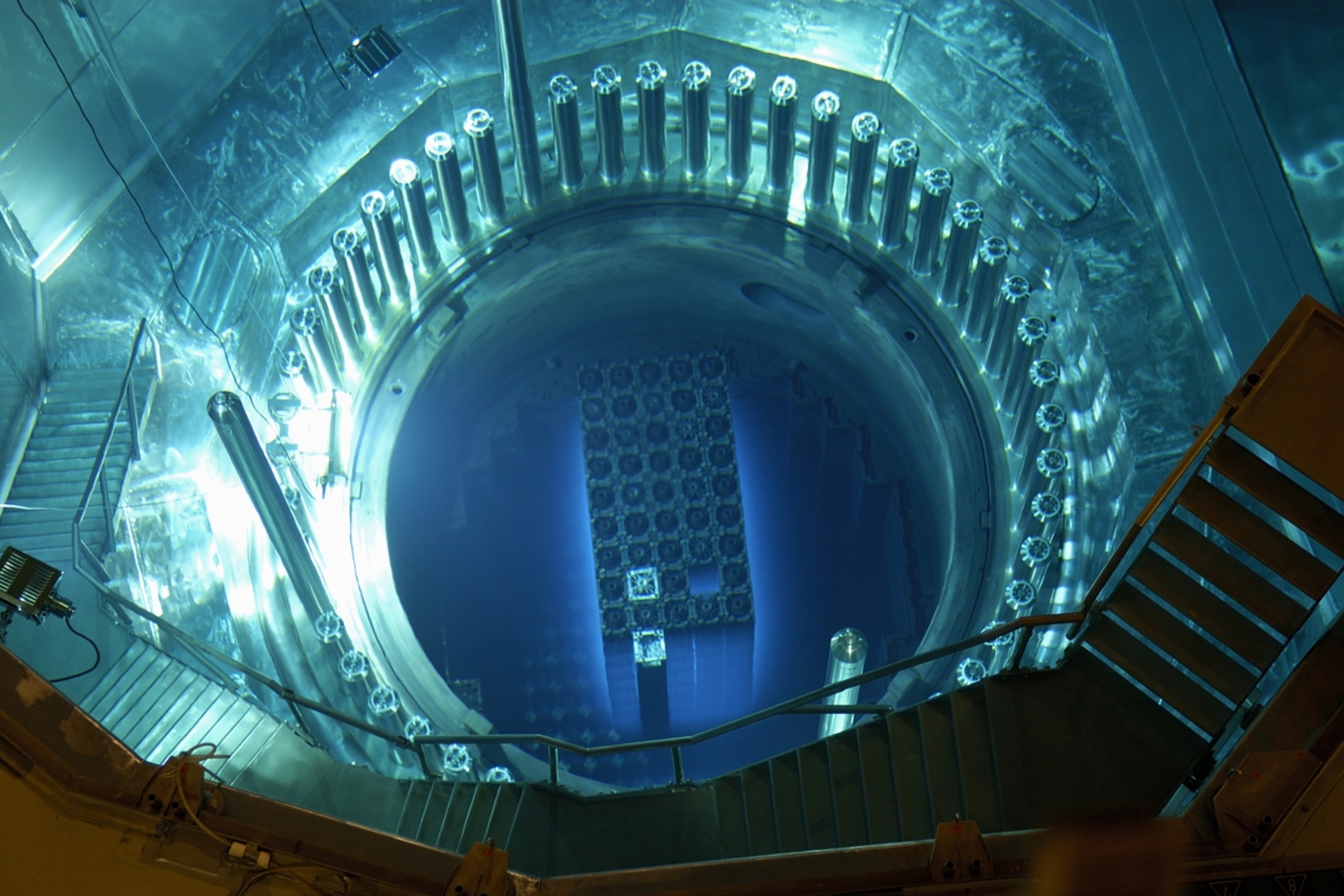

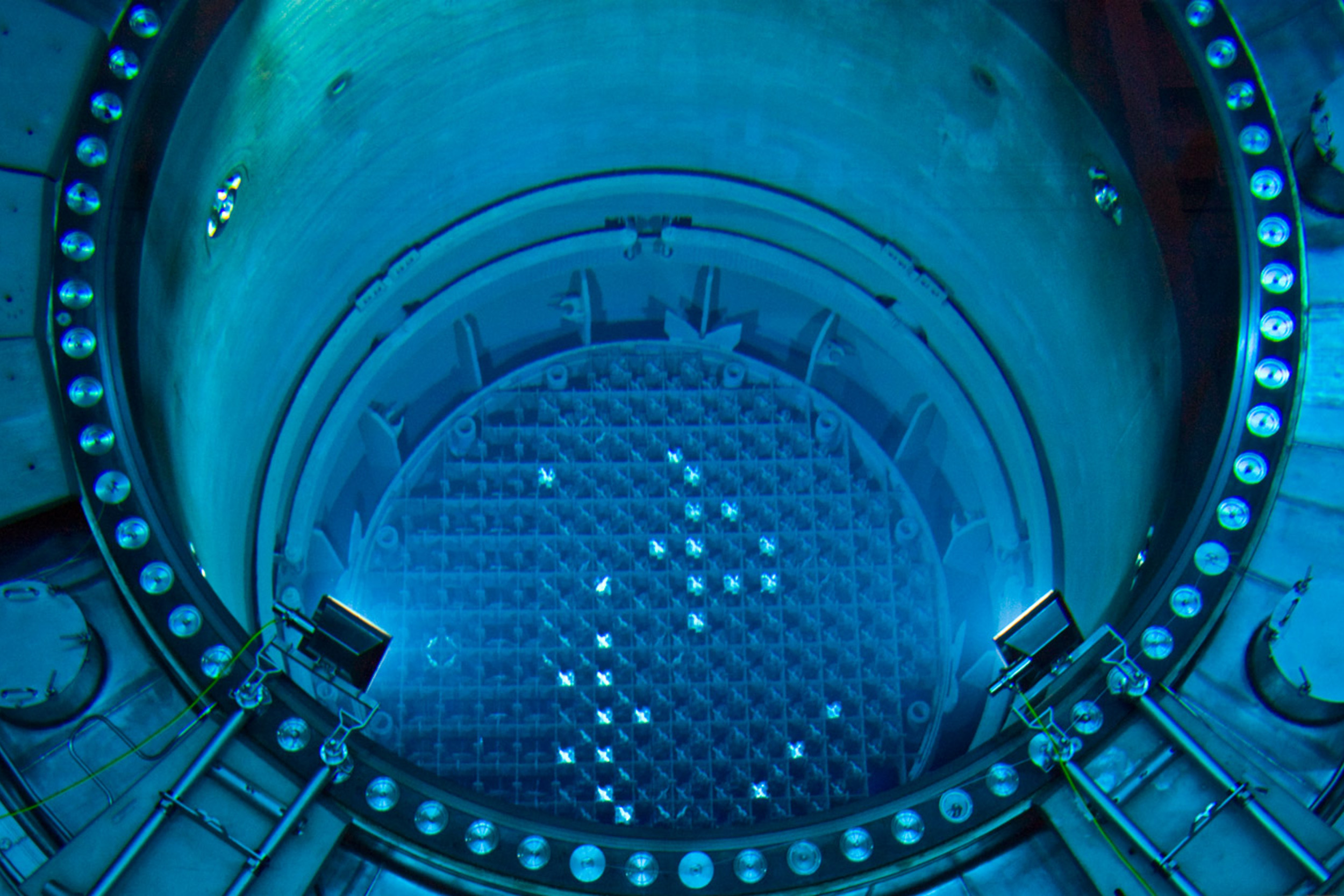

AMET provides welding systems for critical applications in the nuclear industry. We deliver systems for the manufacture of nuclear containment vessels, component repair, and for power generation manufacturing applications. We also provide systems for defense applications (for more information please see Defense Industry page). Some of these systems are located in “hot” areas, so they are “hardened” for exposure. They also include remote operation functionalities, which give the operator control over the system from a safe environment.

THE NEED

Reliable operation and integrity of nuclear components are of great importance for the safety of nuclear facilities.

Precision process control and motion for welding operations is essential to ensure consistent and reliable results. A lack of precision control can result in non-conforming welds, which may lead to premature component failure, potentially resulting in facility damages, expensive component replacement/rework, and losses in productivity.

Quality assurance measures should be built into an automated welding system to verify welds are performed within the system’s programmed welding parameters. If in-process quality assurance measures are not utilized, then small, but potentially ruinous, variations may pass undetected during welding operations, resulting in a faulty or less than ideal results.

Safety is a main concern in the nuclear industry. Great measures are taken to establish and maintain high standards to protect employees and operators with our Nuclear welding automation.

SOLUTION

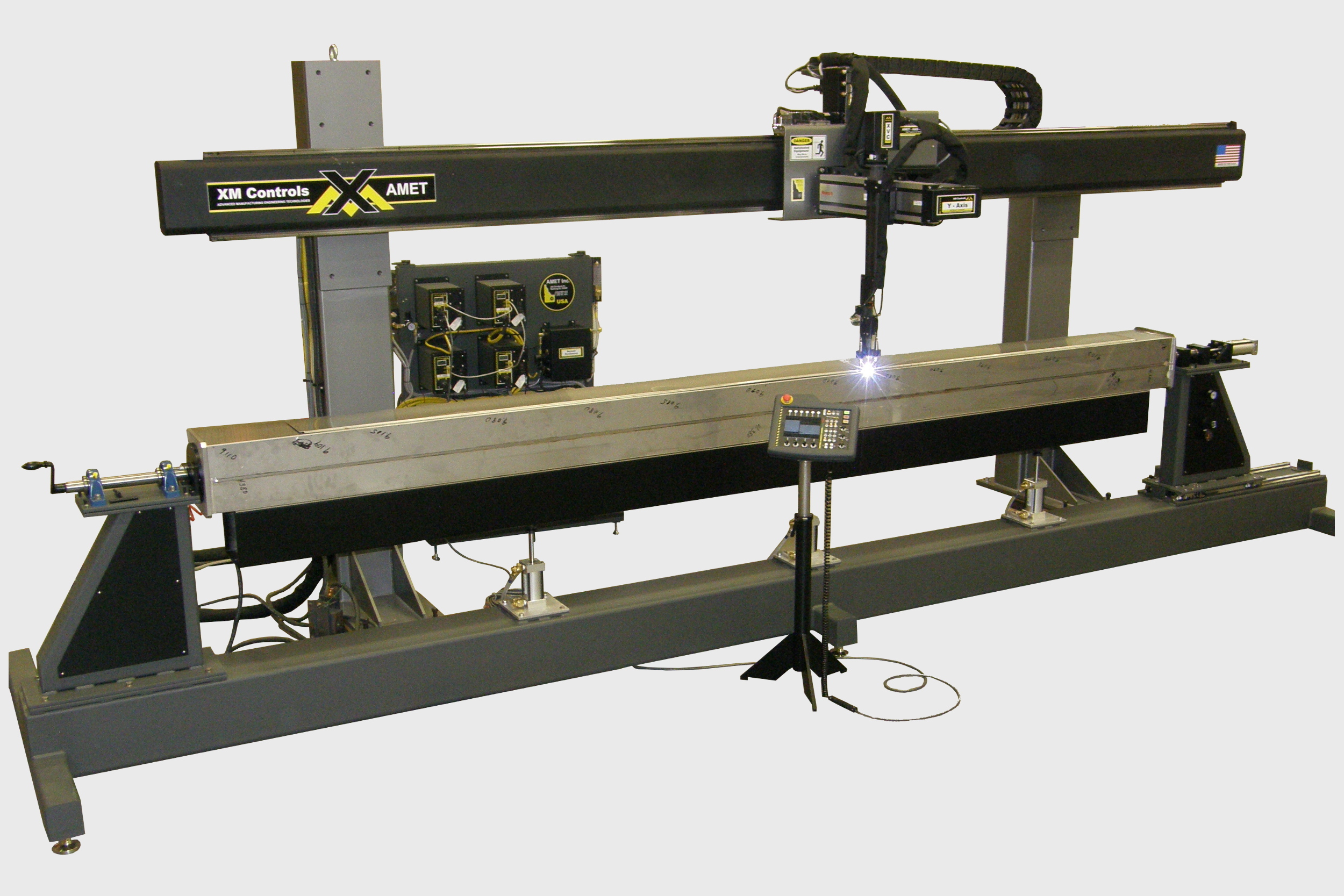

The AMET XM Control package offers a tried-and-true solution for welding in the nuclear industry. Its easy-to-use interface and precise controls provide a complete solution for even the most stringent applications.

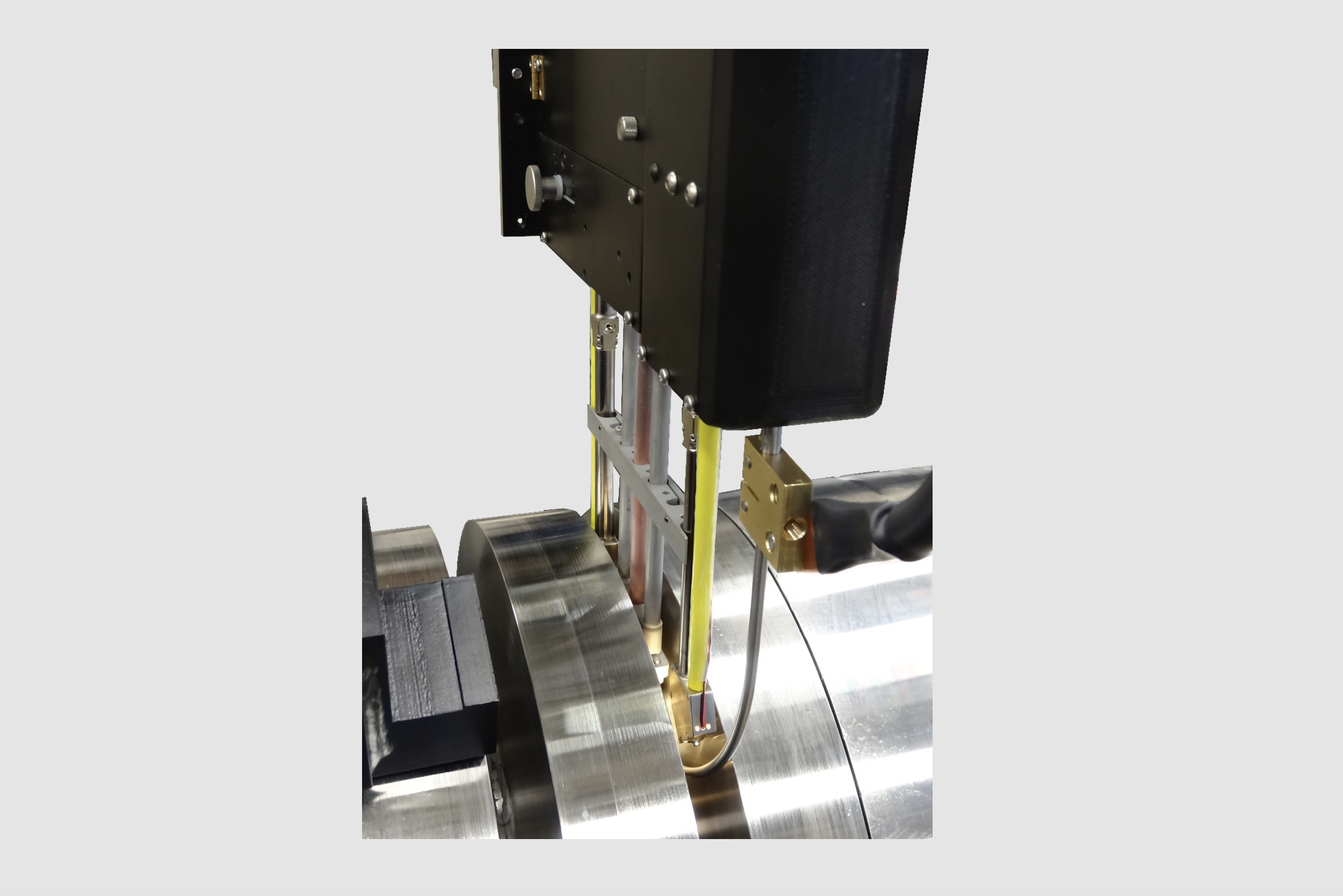

AMET’s controls include encoder-based servo motor driven axes for precise and repeatable motion. This level of precision ensures that parts will be welded consistently and reliably.

Our XM Controller is configurable with Data Acquisition and Tolerance Checking software. The software and each module monitor the process to ensure it is performed as programmed. The system will identify any out of tolerance condition as well as provide different modes to handle out of tolerance conditions. The collected data is stored in the XM Controller, but it can be exported as a .csv file and viewed in Excel or other programs.

Our excellent arc viewing cameras (see the Arc Viewing Camera Systems Page) and monitors can be integrated for high resolution views of the lead and trail of each weld. With our vision systems and the XM Controller, the operator is able to completely control and monitor the system away from the “hot” areas in a safe environment.

RESULT

We have a well established reputation in the Nuclear Industry by providing automation solutions for difficult applications. With over 3 decades of experience, AMET is positioned to provide proven welding automation equipment to meet even the most demanding and stringent needs. We have provided several systems to National Laboratories around the US, and companies around the world for welding nuclear components.

When the XM is equipped with Data Acquisition and Tolerance Checking Software, a level of quality assurance is built-in to ensure each part is welded as programmed.

AMET builds a complete system with the safety of the operators in mind. The XM Controller is designed for operation either near the weld fixture or remotely in a safe environment.

Contact

Please call, write, or email our headquarters in Rexburg, Idaho for more information on how we can better serve you.

355 Dividend Dr

Rexburg, ID 83440