AUTOMATED SEAM WELDING (ASW)

AUTOMATED SEAM WELDING REFINED

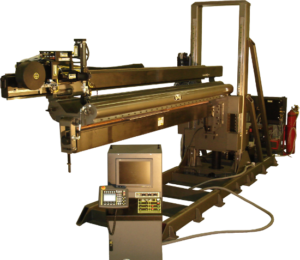

AMET®’s automated seam welding machines are the culmination in the refinement of all the critical pieces of seam welding including controls, precision / reliable motion control, tabletop rigidity, and more. AMET’s Automated Seam Welding Machines are designed as a complete system for performing external and internal linear welds on a wide range of part sizes. Typically these parts are cylindrical or sheets, but other shapes such as conical can be accommodated. Each is equipped with our world-class controls and servo motor driven motion axes for precise control and consistent performance.

These automated seam welding machines, as with all our systems, are designed to provide ease of use, quality, robustness, high-precision, and repeatability. The main structure and base are constructed of thick wall steel tubing to maintain rigidity and extend service life. The carriage runs on precision ground rails with linear bearings.

Many weld processes, such as GTAW, PAW, GMAW, FCAW, and even multi process weld heads can be integrated into our automated seam welding machines.

30+ Years of welding Automation Excellence

AMET® manufactures a full line of external automated seam welding machines. The automated seam welding machines have the following general capacities and specifications:

- Weld Length: 500 to 6000mm (19.6 to 236.2 in) with an additional 125 mm (4.9 in) for run-on and run-off tabs.

- Minimum Diameter Capacity: 75 to 625 mm (2.9 to 24.6 in) ID depending on the length of the seam welder selected.

- Maximum Diameter Capacity: 915 mm (36.0 in) standard capacity, additional capacity is available.

- Carriage Speed: 50 to 4000 mm/min (1.9 to 157.4 in/min)

- Carriage Drive: 2000 mm (78.7 in) seam welders and below include a ball screw drive. Seam welders above 2000 mm include a rack and pinion drive.

- Travel Accuracy: +/- 0.15 mm per 3 meters (.006 in per 9.8 feet).

- Wall Thickness: The mandrel height is adjustable for sheet thicknesses of 0.5 to 10.0 mm (.02 to .39 in).

- Pneumatic Clamping Force: Adjustable up to 65 kg/cm (4367 lb/ft) at 6.9 Bars (100 PSI) air input.

- Carriage Weight Capacity: 150 kg (330 lbs) at a distance of 300 mm (11.8 in) from carriage faceplate.

- Finger to Finger Distance: Adjustable from 3 to 40mm (0.11 to 1.57 in).

- Mandrel Deflection: 2mm (0.08 in) of vertical deflection when full clamping pressure is applied.

Additional features are available to increase the capabilities of these automated seam welding machines. Please refer to the Optional Features section for more information.

The AMET® External Linear Automated Seam Welding machines have several benefits over welding the part manually or using a motorized carriage or “buggy” approach, including:

- The carriage motion is provided by a servo motor driven rack and pinion, which allows the seam welder to achieve consistent welds with an even bead.

- The precision motion of the carriage essentially makes positioning the torch over the centerline of the seam welder bed a one-time operation. A manually operated slide with a hand brake is included for cross-seam adjustment. Once the desired location is reached, the slide can be locked into place with the hand brake and should require very few future adjustments.

- Two manually controlled centering devices are included to ensure parts are loaded in the center of the bed, which helps maintain part uniformity and consistency.

- Ability to maintain part dimensional accuracy due to reduced distortion and weld shrinkage. The weld joint is held firmly in place over the entire length of the part, and the water-cooled mandrel dissipates heat from the weld zone.

- Quality issues related to tack welds are reduced or eliminated because the uniform clamping of the automated seam welding machine makes tacking parts unnecessary in most cases.

- Part loading and welding are relatively easy which reduces operator fatigue and involvement.

- The combination of these benefits greatly reduce the time to prepare a part for welding and the time to finish a part after welding. Rework time, part scrap, and consumables costs are reduced.

XM® Controller

The XM® Controller integrates into all of the major programmable components of the automated seam welding machine. The following axes of motion and components are integrated into the system:

- Carriage Motion: The Linear Motion Module integrates with the servo motor driven weld head carriage to provide programmable motion with override capabilities along the length of the seam welder bed. The linear motion can be programmed by distance (absolute or incremental) or travel time.

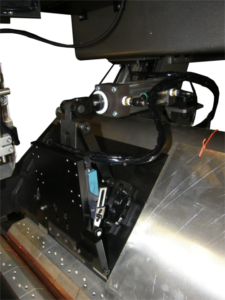

- Torch Vertical Motion: The weld head can be programmed to retract at the end of each weld to facilitate part loading and unloading, then return the proper welding height at the beginning of the weld.

- Welding Power Supply: The Power Supply Module integrates with the welding power supply to program current and voltage from the XM® screen. The programmed values can also be overridden during welding operations.

- Wire Feeder: The motorized wire feed assembly provides programmable feed rate and wire retract. The programmed speed can be overridden during welding operations.

Manual Controls

- Manual slide for controlling the cross-seam (Y-axis) motion of the weld head.

- Manual centering devices are moved into and out of place when loading parts

Automated Seam Welding Controls

- PLC controls for clamping sequence. Clamping is activated by tape switches mounted to the support base structure.

- PLC controls for safety

- Clamping cannot be initiated unless the mandrel latch is closed.

- Clamping cannot be released during weld.

Testimonials

Great Partner

"AMET has been a great partner because they are appropriately positioned to act when we need a new solution engineered or need to service an existing solution. In the end the price of a solution is negligible if it works properly, and the vendor can keep it working through their service efforts. AMET knows these things and services their customers accordingly."

- Matrix Drilling Products

15+ Years

"For over 15 years now I have had the privilege of working with AMET. I have personally seen how AMET Inc. industry knowledge and engineering expertise has enabled my business to increase weld quality and production and allow our clients to improve the strength and durability of their products."

- G. Wright's Welding Ltd.

Exceptional Team

"AMET’s team is exceptional to work with. They look at the provided solution as a whole – from operator interfaces to engineering requirements, they seek to understand the customer’s needs throughout the project. This results in a welding system that is robust, embraced by the workforce, and meets the rigorous requirements of Blue Origin’s vehicles and engines. We’re excited to work with AMET on our vision of millions of people living and working in space."

- Blue Origin

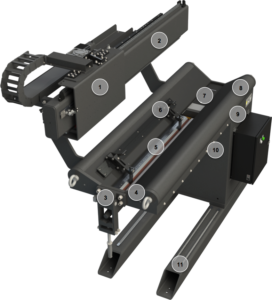

1. A travel carriage rides on four (4) precision linear rail bearing blocks and is driven by the pinion gear mounted to the carriage gearbox and servo motor. Home and travel limit switches are included, further enabling precise and repeatable welds. A cable tray and cable carrier is also included and provides a neat cabling package, as well as extending the life of the cabling and hoses running to the seam welder carriage and weld head.

2. The automated seam welding machines track is stress relieved prior to machining, which maintains tight tolerances and dimensional stability over the lifetime of the equipment. The track is outfitted with precision ground linear rails and a gear rack which provides smooth, repeatable motion resulting in superb welds.

3. A safety interlock switch is provided at the mandrel latch. The integration of this switch prevent the seam welding machines from clamping when the mandrel latch is in an open condition. It also prevents the seam welder from unclamping the part while the weld is in progress.

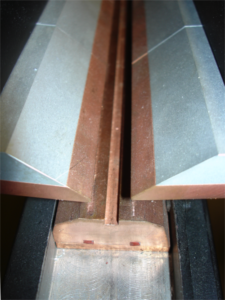

4. Double wall pneumatic hose provides uniform clamping force to each of the clamping fingers along the full length of the weld. A pressure regulator is provided to allow adjustment of the clamping force. The aluminum clamping fingers are fitted with copper fingertips that are reversible to double their service life. The copper fingertips provide excellent heat conduction and aid in chilling the weld zone during the weld. The seam welder’s fingertips may be replaced individually as needed.

5. The finger-to-finger distance between the front and back clamping fingers may be adjusted, thus allowing the fixture to be fine-tuned to the welding process and materials being welded. The fingers are adjustable from 3 to 40mm (0.11 to 1.57 in).

6. Two (2) manually retractable part alignment devices facilitate positioning of the weld joint along the centerline of the seam welder prior to clamping and welding. These alignment devices may be easily repositioned along the length of the seam welder bed, allowing them to be placed appropriately for parts of varying lengths.

7. A built-in storage area is included above the seam welder’s mainstay. Tools or consumables may be stored in this area, keeping them within easy reach and reducing down time.

8. The automated seam welding machines mainstay incorporates an accessible area that may be used for mounting the welding and motion controls, depending on the complexity of the Automated Seam Welding Systems. Having this area available for housing control components helps reduce the number of items that may otherwise have been mounted to the weld head carriage.

9. AMET automated seam welding machines utilize heavy-duty, thick wall structural steel construction to minimize part distortion during clamping. The added mass also provides superior heat absorption and dissipation during the welding process, while at the same time increasing the rigidity and extending the equipment’s service life.

10. The adjustable height seamer mandrel accommodates materials of various thicknesses and is plumbed to accept water cooling to help draw heat out of the weld joint. The seamer mandrel is supplied with one (1) standard copper backup insert. The groove in the insert is machined to match the material type and thickness that is being welded, as specified by the client.

11. Foot-activated tape switches are used to operate the pneumatic clamping and unclamping of the seam welder fingers. A single tape switch is mounted to the back leg of the automated seam welding machine and controls the back clamping fingers, while dual tape switches are mounted to the front leg and control the front and back clamping fingers respectively.

ARC VIEWING CAMERA

ARC VIEWING CAMERA

Arc Viewing Cameras can be added to a GTAW/PAW system giving the operator a view of the weld arc from a remote location. This keeps the operator in a safe location and reduces operator stress and fatigue. Images shown on the monitor are magnified, showing greater detail than what could be observed otherwise. Multiple cameras may be integrated for projects where a view of the lead and trail side of the weld zone is required. See the Arc Viewing Camera page for more information.

AVC FOR GTAW/PAW SYSTEM

An AVC (Arc Voltage Control) Module is added to provide the weld head with automatic arc standoff. The module provides automatic height adjustments to maintain a consistent arc voltage throughout the entire weld, including automatic adjustments on multi-pass welds.

ELEVATING AUTOMATED SEAM WELDING

AMET® offers an Elevating version of the External Automated Seam Welding Machine with increased part diameter capabilities. The AMET® Elevating Seam Welder allows a large range of external welds to be performed without the need of separate equipment. The entire bed and carriage are hydraulically raised to accommodate larger diameters.

This version utilizes the same mandrel and seam welder bed construction as the External version, so the material thickness and clamping capacities are the same. Elevating Automated Seam Welding Machines are built-to-order, so please contact us to discuss your needs and specifications.

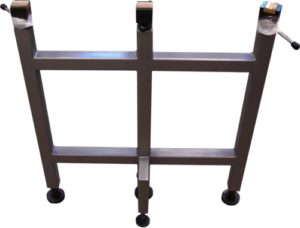

PART LOADING CART

This support device helps the operator load and unload parts into the linear seam welder. The cart or rails are adjustable for various diameters and use rollers so the part position can be adjusted in or out, as well as turned clockwise and counter clockwise. Includes v-way rails for the cart to ride along. NOTE: Maximum Diameter is reduced when using this feature.

FOOT PEDAL SWITCH

An optional foot pedal switch is offered to control the pneumatic clamping of the seam welder in place of the tape switch. This can be beneficial when loading and fitting up the part to be welded.

OPTIONAL FINGERTIPS

In some applications fingertips made from steel, stainless steel or chrome plated fingertips are required. AMET® can additionally provide Continuous Clamping Strips made from copper. These copper strips are recommended when welding thin materials or materials where small amounts of oxygen are a concern.

MANDREL CENTER SUPPORT

In some applications, an undersized mandrel is required. However, when clamped, the mandrel will deflect beyond allowable tolerances. In these situations, AMET® can provide a mandrel center support, or in some cases, a series of supports. The supports are adjustable and provide the mandrel with additional load paths to counter the deflection from the clamping forces.

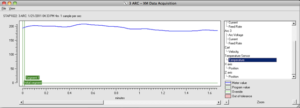

DATA ACQUISITION AND TOLERANCE CHECKING SOFTWARE

DATA ACQUISITION AND TOLERANCE CHECKING SOFTWARE

Data is collected and analyzed in real-time to ensure all modules are within the set tolerances. The data points can be displayed graphically on the display or exported as a .csv file and viewed on a program such as Microsoft Excel. Files can be exported through one of the USB or Ethernet ports on the XM® or XPro Controller.

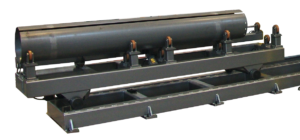

SHEET LOADING ROLLERS

Optional Sheet Loading Rollers are available with either hydraulic or pneumatic cylinders. With the rollers in the extended position, the sheet material is raised above the seam welder mandrel when loading and when pulling the material through the seam welder. With the rollers retracted the material drops in place over the seam welder mandrel and is presented for clamping and welding. Depending on the length of the seam welder, this option may include between three (3) and six (6) rollers per side, front and back.

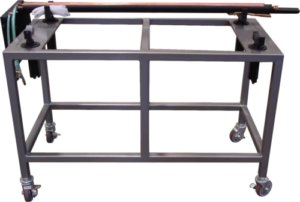

MANDREL CART

When a seam welder is ordered with multiple mandrels, the optional Mandrel Cart may also be selected. The Mandrel Cart provides a safe manner to change out from one mandrel to another by wheeling the cart into position, raising the adjustable mandrel supports on the cart and then unbolting the mandrel from the mainstay. Once freed from the seam welder mainstay the cart can be repositioned so that the secondary mandrel may be installed. This provides an effective method of changing out the mandrels while keeping personnel safe and speeding up the changeover process.

DUAL PRESSURE CLAMPING

DUAL PRESSURE CLAMPING

Dual Pressure Clamping allows the operator to use a lower pressure to clamp the part edges into position during the fit-up process of loading the part into the seam welder. Once the part is correctly positioned, the clamping pressure, and thus the clamping force, may be increased to keep the parts from shifting during the welding process. With the Dual Pressure Clamping option, separate pressure regulators and pressure gauges are provided. This allows the clamping pressures to be adjusted independently.

PNEUMATIC CENTERING DEVICES

The standard centering devices are manually moved in and out of position. The Pneumatic Centering Devices are air driven so they work semi-automatically. The operator toggles a switch to lower or raise these centering devices (1 pair). Additionally, the Pneumatic Centering Devices may also be activated as a step in either the pre-weld or post-weld automation.

PLC CONTROLS

PLC CONTROLS

We integrate components into our controls for automating additional functions other than the welding process. These components include safety equipment such as automatic weld screens or curtains that are programmable to automatically open and close at the end or beginning of each weld. We can also integrate additional tooling such as automated part loading equipment.

PNEUMATIC LATCH

PNEUMATIC LATCH

The standard latch requires that the operator open and close it manually. The Pneumatic Latch, on the other hand, is actuated by a pneumatic cylinder and allows the operator to press one button to open or close the latch. By using a digitally controlled pneumatic solenoid, the operation of the latch may be included as one of the steps in the pre-weld or post-weld automation. A safety interlock switch is included as part of this optional feature package.

INTERNAL SEAM WELDER

AMET® offers an Internal version of our Seam Welders with an equal focus on precision and robustness as the External version. These Seam Welders are engineered to provide the smallest envelope (minimum part diameter) possible, while providing a virtually unlimited maximum part diameter. For large diameters, additional equipment such as an overhead crane or forklift may be required for supporting parts.

Internal Seam Welders are capable of flat sheet seam welding as well as clamping and welding thicker materials. Unlike the External Seam Welder, the base and the mandrel are an integrated structure with supports along the entire length of the seam welder bed. This allows us to increase clamping capabilities without risking damage to the base or mandrel. These are built-to-order, so please contact us to discuss your needs and specifications.

MANDREL INSERTS

The standard mandrel insert is machined from copper, but some welds require a different insert to back up the weld. In other welding processes copper is not allowed to contact the material when welding. For these welds AMET® can offer mandrel inserts made from steel, stainless steel, or the mandrel insert may even be chrome plated.

When welding materials such as stainless steel and titanium, gas coverage on the back of the weld is desirable. For cases such as these, AMET® offers a copper insert machined with a gas channel and a series of staggered holes, spaced every 50 mm (2 in) to allow shielding gas to pass to the backside of the weld joint and improve weld quality.

INTEGRATED PURGE/BACKING GAS

This package includes a gas union, digital solenoid, manual flow meter, and a gas line from the solenoid to the gas union for purging or backing gas capability. The digital solenoid is integrated with the XM® and XPro Controllers for programmable and manual on/off control of the gas. Programmable flow control is also available.

BAR CODE PROGRAM SELECTION

Weld programs can be automatically selected by scanning a bar code associated with a specific part. This can help eliminate the incorrect program being loaded and run. Beneficial if many different parts are to be welded and operator needs to frequently switch between weld programs. Includes the bar code scanner and the necessary software to integrate with the XM® or XPro Controller.

HEAVY-DUTY OPTION

A Heavy Duty version of the Internal Seam Welder is available which includes more robust structural components to withstand higher clamping forces. This version is rated for clamping material thicknesses ranging from 0.8 to 16 mm (0.03 to 0.63 in). The clamping force for the Heavy Duty version is adjustable up to 134 kg/cm (9,000 lb/ft).

MAINSTAY RISER

For projects that require a maximum OD capacity greater than the standard 910mm (36 inches), AMET® is able to provide an optional Mainstay Riser. These are available in various heights which, when installed, will increase the seam welder’s maximum OD capacity anywhere from 1,050mm (42 inches) to 1,800mm (72 inches). Mainstay Risers are produced in sizes having 150mm (6 inch) increments.

CUSTOM MANDRELS

Not all seam welding applications are the same; because of this, AMET® offers custom mandrels based directly on the end user’s project requirements. Some projects require the ability to weld smaller diameter parts than allowed by the standard sized mandrel. One option for these scenarios is an undersized mandrel, allowing smaller diameter parts to be welded along the full length of the seamer. Depending on the material thickness this may require a mandrel support.

In some situations, this smaller diameter capacity is only needed on parts that are less than the permissible weld length. For these projects a stepped mandrel may be available where the latch end of the mandrel is machined with a smaller diameter, which then increases in diameter significantly in order to counter the clamping forces.

RETRACTING MANDREL INSERT

The mandrel is “split” into two sections, an upper section that holds the mandrel insert, and a lower section that provides structure and support to the upper section. The portion that holds the insert is secured through a series of levers to the lower portion of the mandrel. The levers act as a hinge assembly, allowing the insert section to move either up or down into position. This motion is achieved by a hydraulic cylinder located inside the vertical mainstay section. With this design the assembly has at least 30 mm (1.25 in) between the fingers and the insert when in the retracted position. This simplifies the loading and unloading of parts. This feature may be added to most seam welding machines, but is typically utilized on the Internal Seam Welder. This option may add 100 mm (4 in) to minimum part diameter for any given length of seam weld machines.

STEEL HOSE MANUFACTURING

STEEL HOSE MANUFACTURING

AMET has helped clients automate their welding processes for steel hose manufacturing. Seam welding is an efficient way of producing custom tubing from thin wall steel and stainless steel for use in a wide range of industrial and exhaust applications. Once welded, the tube may be outfitted with specialized end fittings or hydroformed into corrugated tube for flexible connections.

FUEL TANKS

FUEL TANKS

Often constructed of stainless steel or aluminum, fuel tanks require full penetration high integrity welds to prevent leaks. AMET’s welding systems are capable of welding fuel tanks in a wide range of shapes and sizes.

TANKS / PRESSURE VESSELS

TANKS / PRESSURE VESSELS

Stainless steel, or other materials, can be used to form tanks or pressure vessels of various sizes for the food and beverage or pharmaceutical industries. These vessels are typically fabricated using GTAW, PAW, or VPPAW, but with each process, AMET can provide a fully automated turnkey weld system to meet your needs.

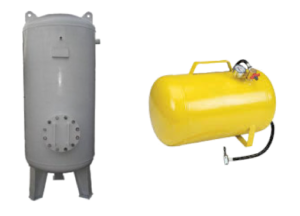

AIR CYLINDERS

AIR CYLINDERS

Cylinders used for pressurized air storage such as air compressors, portable air tanks, and truck brakes. Manufacturing of these cylinders requires longitudinal and circumferential welds.

Useful Links and Information:

Links

Contact

Please call, write, or email our headquarters in Rexburg, Idaho for more information on how we can better serve you.

355 Dividend Dr

Rexburg, ID 83440