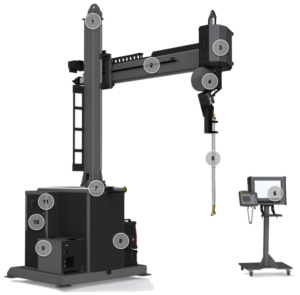

COORDINATED MOTION CLADDER (CMC-66)

Smart cladding of large parts & non-circular bores

Unlike standard cladding systems that use a positioner to rotate the part around a bore torch, AMET’s Coordinated Motion Cladder features a continuous rotating weld head coordinated with a precision rotating column & boom to allow the torch to move inside the bore, so that the part can remain stationary. This approach is advantageous for large parts or non-circular bores. The precision coordinated motion of the weld head, boom, column lift, and column rotation, allow us to perform cladding, overlay, or hard-surfacing on cylindrical and non-cylindrical part geometries without a positioner. The systems can accommodate standard intersecting bores as well as off-center off-angle bores.

The coordinated motion allows parts to be placed and processed anywhere within the operating envelope, so multiple parts can be placed and pre-heated while another part is being clad. Touch sensing between the torch and the sidewall automatically determines part location and bore center. AMET’s precision AC hotwire power supply is included to increase deposition rates without increasing welding current.

The CMC-66 is available in three versions: S, SB, and LX.

30+ Years of welding Automation Excellence

The CMC-66 Bore Cladder is a precise and capable system with automated overlay systems for cladding of the entire bore. The CMC has the following capacities:

- Horizontal Motion: Precision boom motion with 72 in (1829 mm) of stroke

- Vertical Motion: Precision column motion with 72 in (1829 mm) of stroke

- AVC (Arc Voltage Control) is built into both the vertical and horizontal axes of the manipulator to provide vectored AVC

- Column Rotation: Servo motor controlled with 270 degrees of rotation

- Weld Head Rotation: The weld head is capable of continuous rotation in either direction

- Bore Diameter Range: 3.5 in (89 mm) to 72 in (1829 mm) bore diameter

- Bore Height: Maximum of 63 in (1600 mm)

- Part Geometry Capabilities: Cylindrical, racetrack, and oval shaped parts with off-center and off-angle intersecting bores

- Wire Feeder: 1 to 500 in/min (25 to 12700 mm/min) programmable wire feed speed

- Hotwire Power Supply: 200 Amps up to 20 Volts

- Welding Power Supply: Output Min: 5 Amps, Max: 300 Amps at 100% duty-cycle or 350 Amps at 40% duty-cycle

- Water Circulator: Capable of cooling torches up to 500 Amps

- Water-cooled Bore Torch:

- Minimum Bore Diameter: 3.5 in (89mm)

- Max Weld Current: 350 Amps at 100% duty-cycle

- Max Hotwire Current: 70 Amps

- Reach: 48 in (1219 mm)

The CMC-66 offers the following benefits over traditional manipulator and turntable or manual bore cladding systems:

- The continuous rotation weld head eliminates the need for large and expensive turntables or positioners to rotate large parts.

- On traditional bore cladding systems, aligning the bore to be clad can be challenging, especially if the bore is significantly offset from the center of mass. With the CMC-66 and its automated overlay systems, bore locations can be quickly programmed without time consuming aligning on a turn table.

- Preheating the part, when necessary, is significantly easier if the part is stationary. Heating blankets do not require slip-rings for a stationary part like they normally would for a rotating part.

- Since parts are placed on the floor within the envelope of the rotating column and boom, multiple parts can be prepared or preheated while another part is being welded, improving system utilization and throughput.

- Vectored AVC is included for maintaining a constant arc standoff no matter which plane is being welded. The AVC can be programmed from 0 to 90 degrees. Zero (0) degrees for horizontal welds on the wall of the bore, 45 degrees for blind holes, and 90 degrees for vertical welds. The X, Y, and Z axes are integrated together and each one takes continuous samples to maintain the proper arc standoff.

- The hotwire power supply significantly increases deposition rates over cold wire GTAW. Rates are closer to the deposition rates of GMAW but with cleaner higher-quality GTAW welds.

The XM Controller

The XM Controller integrates directly with the following servo motor driven axes of the CMC-66: weld head rotation, column rotation, horizontal boom motion, and vertical boom motion. The control package features a coordinated motion module that allows these precision axes to work together harmoniously much like the axes of a CNC milling machine.

The XM Controller, in conjunction with an integrated touchscreen monitor, provides standardized menus specific to various bore cladding geometries. Part geometries including: diameters, heights, angles, intersecting bore locations, and cladding pitch are easily entered using the menus displayed on the touchscreen monitor, which includes a rendering of the part that updates as parameters are changed. Once all of the parameters are entered, the weld path is automatically generated and displayed for complete cladding of the bore.

There are three different versions of the CMC-66. Each version offers a different level of cladding capability.

Standard Bore Cladding – S-Version

Includes spiral or step cladding of circumferential, oval, or race-track bores.

Intersecting Bore Cladding – SB-Version

Includes all S-Version capacities, plus additional capabilities for intersecting bores and seal welds.

Complex Intersecting Bore Cladding – LX-Version

Includes all SB-Version capacities, plus additional capabilities for off-angle and off-center intersecting bores.

Testimonials

Great Partner

"AMET has been a great partner because they are appropriately positioned to act when we need a new solution engineered or need to service an existing solution. In the end the price of a solution is negligible if it works properly, and the vendor can keep it working through their service efforts. AMET knows these things and services their customers accordingly."

- Matrix Drilling Products

15+ Years

"For over 15 years now I have had the privilege of working with AMET. I have personally seen how AMET Inc. industry knowledge and engineering expertise has enabled my business to increase weld quality and production and allow our clients to improve the strength and durability of their products."

- G. Wright's Welding Ltd.

Exceptional Team

"AMET’s team is exceptional to work with. They look at the provided solution as a whole – from operator interfaces to engineering requirements, they seek to understand the customer’s needs throughout the project. This results in a welding system that is robust, embraced by the workforce, and meets the rigorous requirements of Blue Origin’s vehicles and engines. We’re excited to work with AMET on our vision of millions of people living and working in space."

- Blue Origin

1. The precision column lift is achieved through a servo motor driven rack and pinion drive along precision rails. Precision lifting of the boom provides the system with the necessary vertical motion for continuous spiral or step index cladding. A flexible cable carrier is included to organize and protect the life of the cables during motion.

2. The precision boom drive features a servo motor driven rack and pinion drive along precision rails for horizontal motion of the bore torch. The precision drive is controlled and driven by an AVC (Arc Voltage Control) module for constant arc standoff during cladding. A flexible cable carrier is included to organize and protect the life of the cables during motion.

3. The continuous rotation weld head allows for sustained cladding of parts without the necessity to stop and “unwind” the cables and hoses. The weld head rotation is servo motor driven with a slip ring to ensure continuous operation without tangling the cords or hoses.

4. A 4-roll wire drive assembly that is driven by a servo motor with encoder feedback provides precision wire delivery. Wire feed speed, start delay, and wire retract are each programmable by the XM Controller. The wire feeder offers high-precision wire delivery with an accuracy of +/- 1% of the programmed speed. The wire feeder is mounted below the rotation axis of the weld head to prevent wire tangling.

5. The AMET bore torch is water-cooled and equipped with the necessary components for hotwire feeding. The torch is rated at 350 Amps at 100 percent duty-cycle.

6. The XM Controller operates in conjunction with a touchscreen monitor for entering part dimensions and weld parameters. Once the dimensions and parameters are entered, the weld path is automatically generated including the number of passes necessary for part completion. The touchscreen monitor displays a rendering of the part and the real-time location of the torch. Part location and orientation are configured by touching the tip of the torch to the inner wall of the part in three different locations. Using these reference points the part location and orientation are automatically determined.

7. The column (mast) has precision rotation that combines with the rotating weld head to provide the necessary circular motion for bore cladding. The 270 degrees of rotation is servo motor driven and allows the CMC to have a much larger work envelope than most cladding systems. Anywhere within the reach of the manipulator can be used as work space as opposed to traditional systems with a positioner or turn table.

8. A 350 Amp DC GTAW welding power supply will be integrated into the system for programmable control of the weld parameters. The power supply is capable of cladding with a wide range of filler metals including hard metals like Inconel. A water chiller is included to circulate water for cooling the bore torch to prevent damage from overheating. The power supply stacks on top of the water chiller to conserve space.

9. AMET’s precision hotwire power supply is built using AC instead of DC electrical components. This helps reduce arc deflection that is common on DC hotwire systems. It also produces a more precise and consistent sinewave for more reliable operation. The current and voltage are adjustable up to 200 amps and 20 volts respectively.

10. An electrical control cabinet is included to provide a central location for all control modules and electrical components. The cabinet is equipped with an air conditioner to protect the electrical equipment from overheating in hot environments. Also included in this package is a single point power distribution that provides fuse-protected power to the entire system from a single primary power circuit (provided by client).

11. A GTAW sensor box is included to provide integration of the gas and water sensors. A digital solenoid and manual flow meter are incorporated for programmable on/off control of the shield gas. A gas sensor is also included to detect the presence of gas. If no gas is sensed, the XM will receive an error. A water fault sensor is included to ensure water is flowing to the torch to prevent damage due to overheating.

ADDITIONAL MANIPULATOR TRAVEL

An additional 24 in (610 mm) of precision travel can be added to either the vertical or horizontal travel axes of the manipulator. These additional capacities increase the work envelope so larger parts can be clad than with the standard version.

ARC VIEWING CAMERA

ARC VIEWING CAMERA

Arc Viewing Cameras can be added to a GTAW/PAW system giving the operator a view of the weld arc from a remote location. This keeps the operator in a safe location and reduces operator stress and fatigue. Additionally, the image that is shown on the monitor is magnified and shows greater detail than what could be observed without the camera. Multiple cameras may be integrated for projects where a view of the lead and trail side of the weld zone is required. Please see the Arc Viewing Camera page for additional information.

PRECISION WORK PLATFORM

Up to three (3) precision work platforms can be added to the CMC-66 system. The work surfaces are precision ground and machined with t-slots to aid in consistent part placement and holding.

DUAL WIRE FEED DRIVES

An additional wire feeder can be added to the weld head. The wire feed package includes: a 30-pound wire reel, cover, 4-roll precision drive assembly, servo motor, encoder, control module, and hotwire nozzle. The addition of the wire feeder package increases wire deposition to the weld puddle, increasing throughput and productivity.

INTERSECTING BORE CLADDING

Intersecting Bore Capabilities

The cladding software comes in three versions. The standard bore cladding (S), intersecting bore cladding (SB), and complex intersecting bore cladding (LX). The SB and LX versions are upgradable options for the standard system.

Intersecting Bore Cladding – CMC-66SB

Includes CMC-66S capabilities and additional software for intersecting bores and seal welds.

Complex Bore Cladding System – CMC-66LX

Includes CMC-66SB capabilities and additional software for off-angle and off-center bores.

.

RACETRACK BORE

Oval-shaped or “racetrack” bores can be easily programmed and clad with the CMC-66 bore cladder. Additional equipment or specialized fixtures are not required to completely clad the bore from bottom to top.

INTERSECTING BORES

INTERSECTING BORES

Parts with intersecting bores can be welded with AMET’s welding systems. This is facilitated by our use of intelligent software matched with premium hardware.

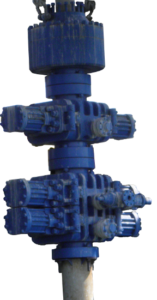

BALL VALVES

BALL VALVES

Ball valves require corrosion-resistant overlay for use in the oil and gas industry. Our systems are programmable to automatically clad around the opening of the ball for a completely automated solution.

GAS VALVES

GAS VALVES

Valves used in the oil and gas industry often require corrosive resistant coatings on sections of the inner diameter or along the entire length. Bore cladders are used to apply the corrosive resistant metals to the ID of valves.

BLOWOUT PREVENTER

Blowout preventers require corrosion-resistant overlays of the bores and components to ensure they can withstand harsh oil and gas environments. Our systems and controls provide an excellent solution for BOPs whether your company is the primary manufacturer or performs repairs.

Useful Links and Information:

Links

Contact

Please call, write, or email our headquarters in Rexburg, Idaho for more information on how we can better serve you.

355 Dividend Dr

Rexburg, ID 83440