AEROSPACE & AVIATION

AEROSPACE / AVIATION

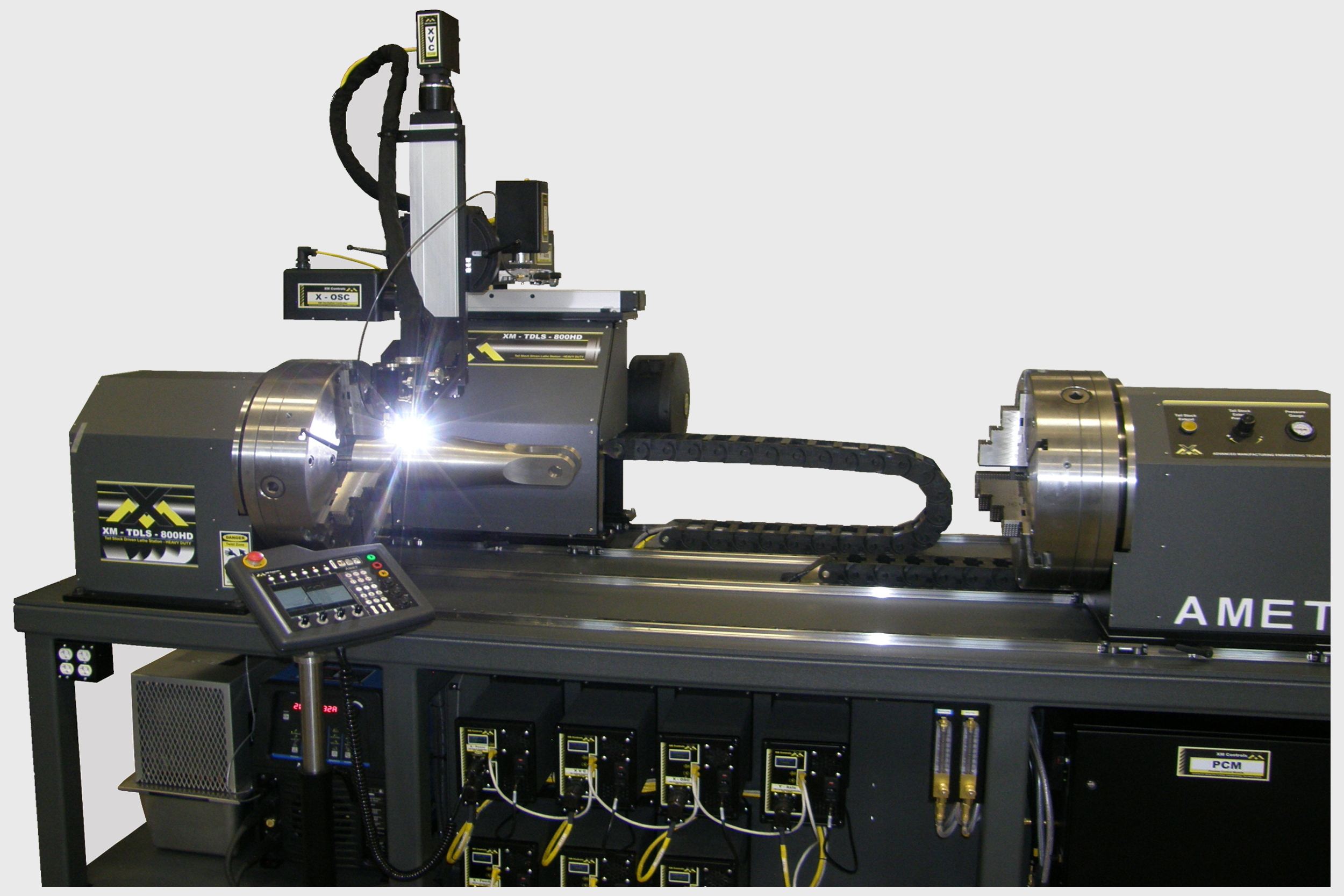

AMET’s Automated Jet Engine Weld Repair Systems are designed and manufactured for aerospace companies since 1992. We specialize in precision tooling and controls for our customers’ advanced manufacturing process needs and component alloys.

The single controller approach that AMET utilizes allows the operator to be stationed away from the weld zone when welding large parts, while still being able to monitor the process using live video feeds. With a variety of aerospace welding automation processes and system types available, almost any part can be accommodated.

THE NEED

Extreme precision, accurate data acquisition, and consistent repeatability are necessary in the aerospace welding automation industries. There are many applications in these industries with tight tolerances.

Examples of parts welded by aerospace companies include fuel cells, compartment sections, engine mechanisms, and other critical components. Materials used in the manufacturing of these parts include corrosion resistant superalloys, stainless steel, and aluminum. Some alloys of aluminum require VPPAW or VPGTAW welding. This can be a difficult process to control consistently.

SOLUTION

With our extensive experience and precision controls, we offer solutions for a wide range of industry applications. All of our welding axes include encoder-based servo motors. This allows us to control not only velocity but the positioning of each axis as well. With the ability to control positioning, we can ensure parts are welded consistently. With our full line of welding fixtures, we can meet the needs of most applications.

Our XM Controller is configurable with Data Acquisition and Tolerance Checking software. The software collects data for each axis of motion as well as each welding parameter. If any of the parameters is out of the tolerance range, then the welding program can be automatically terminated.

To ensure complete control of the VPPAW and VPGTAW weld processes, we have developed our own power supply called the VPC-450. Our power supply allows us to precisely control all aspects and parameters of the variable polarity welding processes, including switching speeds. We even offer AVC with this welding process. We have numerous XM Controlled variable polarity systems around the world.

RESULT

AMET offers completeAutomated Jet Engine Weld Repair Systems. From the welding fixtures to the control components, we build and integrate the entire system in-house. With over 25 years of welding experience, we can provide a high return on investment by providing a reliable and well-supported system for years of consistent operation.

Our Automated Jet Engine Weld Repair Systems are proven. We have constructed several systems that are currently being used throughout the US, Europe, and Asia. These systems are used for manufacturing components from pneumatic hoses to rocket fuel tanks. We can provide a system to meet your project requirements.

Since our components are built in-house, we have the knowledge and ability to provide prompt, helpful, and courteous service after the sale to ensure downtime is kept to a minimum.

Contact

Please call, write, or email our headquarters in Rexburg, Idaho for more information on how we can better serve you.

355 Dividend Dr

Rexburg, ID 83440