POWER

POWER

The Power Industry is comprised of plants that utilize a fuel source such as natural gas or coal to heat water to create steam and generate power. Welded components used in the power generation industry are usually for high-pressure applications. Our Power Plant welding automation provides the required consistency and integrity to ensure that each component meets the customer’s requirements for their parts in these environments.

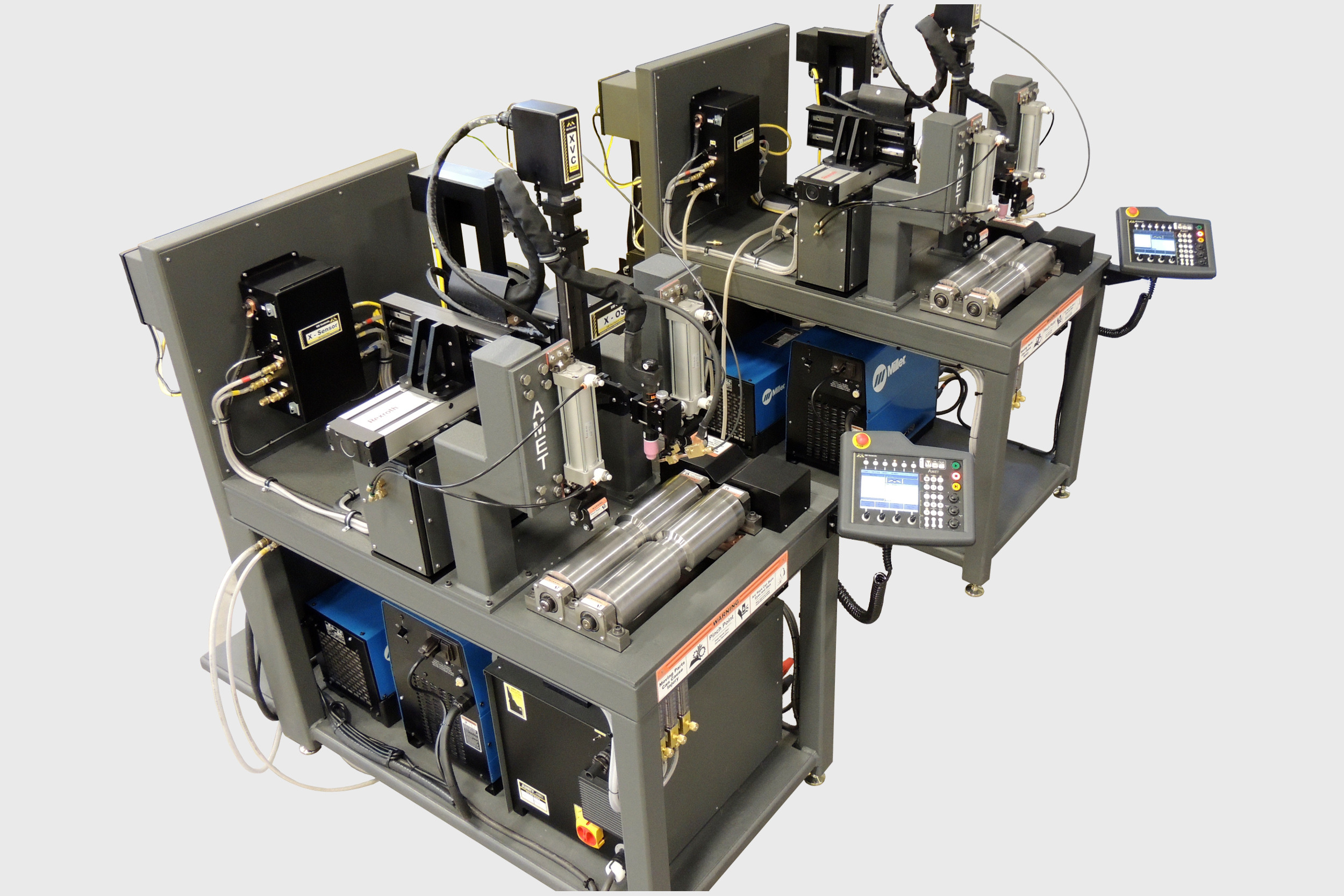

We provide precision power plant welding automation solutions for the manufacturing of boiler components and pressure gauges. Our user friendly interface and powerful controls combined with precision motion components ensure that we can provide a solution for virtually any application.

THE NEED

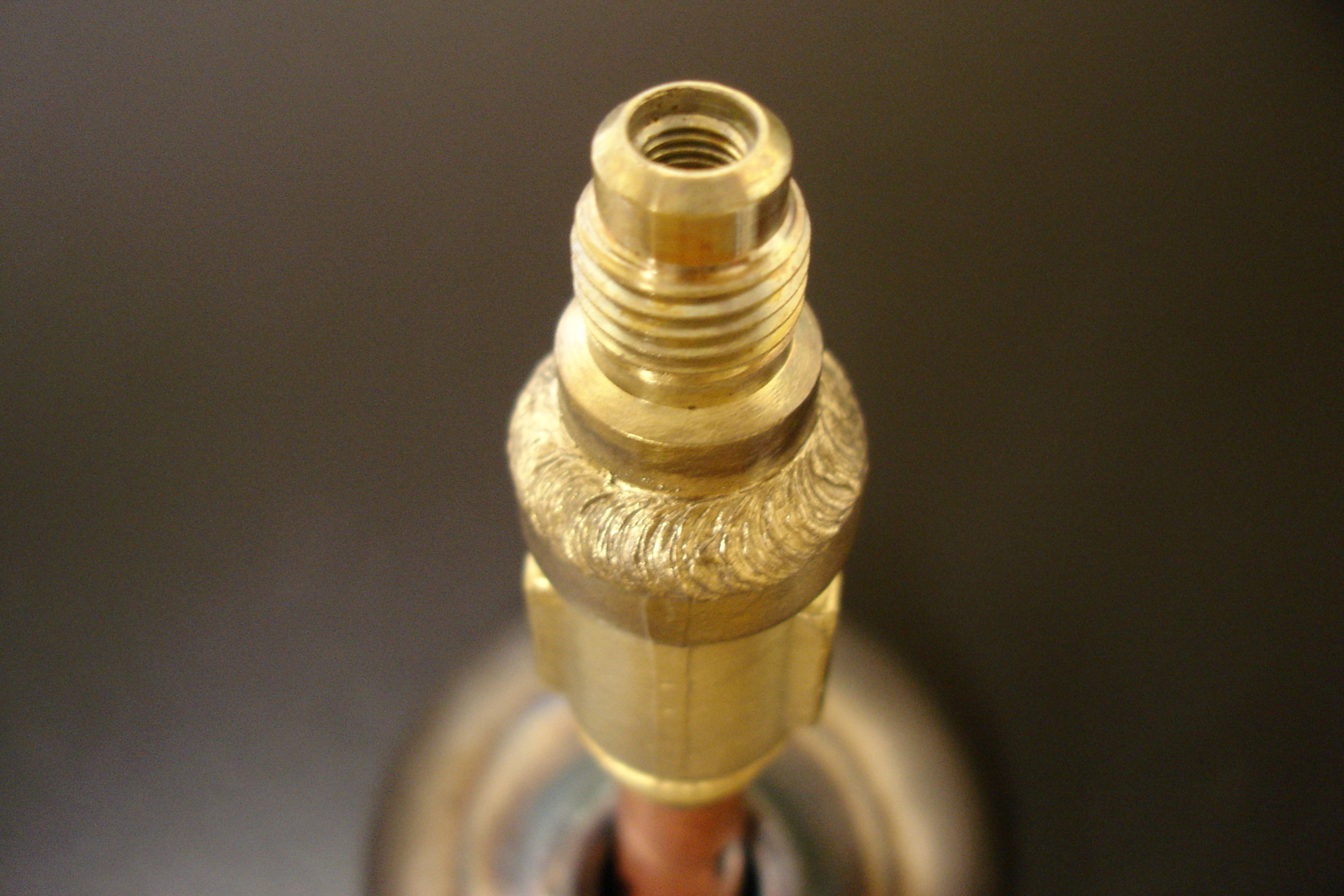

The majority of components in this industry are used in high pressure situations, so the integrity of the welds is essential. Consistency is necessary to maintain a high quality part. To achieve this level of consistency on an automated system, there must be precise velocity, positioning, and welding power supply control. Our Power Plant welding automation systems do just that.

SOLUTION

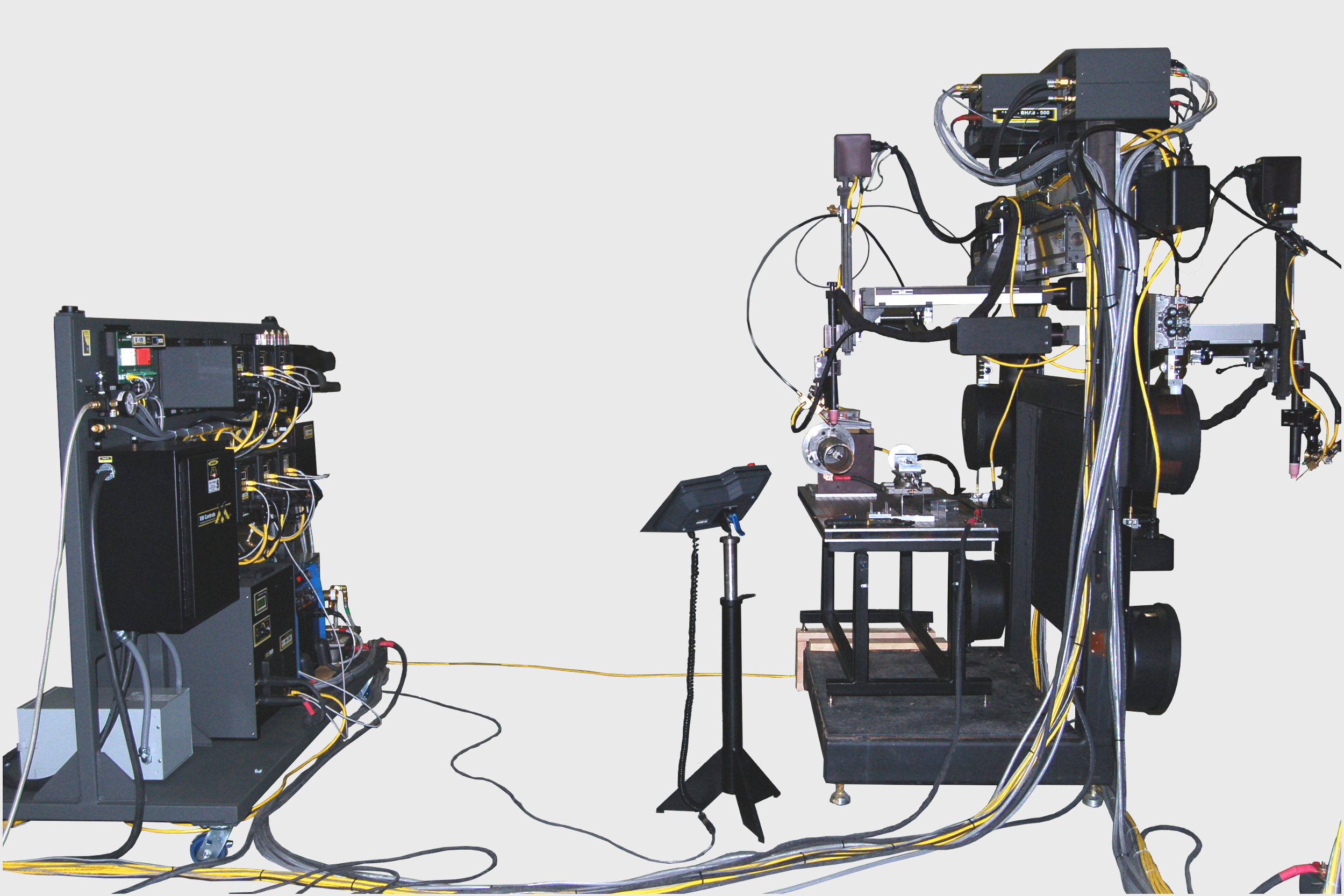

One of the greatest advantages to AMET systems is that we combine precision process control with accurate encoder-based servo motion control into a single controller. AMET’s single controller approach is ideally suited for performing precise welds on a wide range of parts or for repetitious tasks where consistency and uniformity are crucial. Our controls also integrate directly with other sensors and safety equipment that may be necessary for these automation applications.

We offer complete lines of lathes, manipulators, positioners, seam welders, and weld heads to fulfill the requirements for virtually any application. Each weld fixture is built to provide robustness to increase consistency and longevity of the system.

RESULT

Our systems are proven. We have several power plant welding automation systems currently being used to produce high quality components for this industry. These systems are utilized to create a wide range of parts.

Our Power Plant welding automation systems are built for longevity. We produce all of our controls and software in- house, which allows us to provide years of service after the sale. Our ability to diagnose, repair, and service each system prevents obsolescence and provides a good return on investment.

One of our greatest strengths is our knowledgeable customer service department that will support each system expertly and courteously.

Contact

Please call, write, or email our headquarters in Rexburg, Idaho for more information on how we can better serve you.

355 Dividend Dr

Rexburg, ID 83440