WELDING LATHES

Precision Welding Lathe systems that offer accuracy, repeatability, and versatility

Welding Lathe Systems

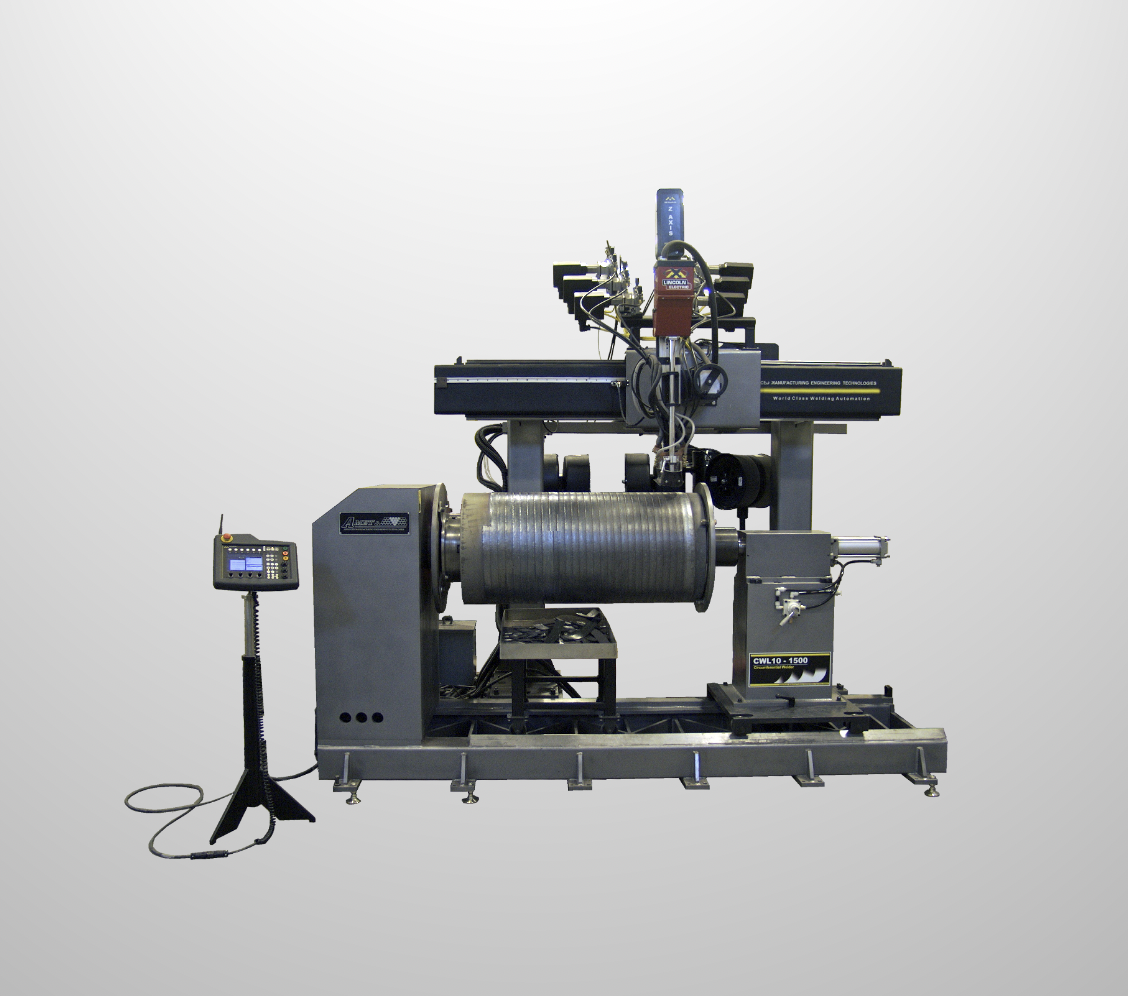

AMET® Welding Lathes are constructed of high-precision quality components to provide the rigidity and precision demanded by critical welding applications. Precision bearings and rails provide smooth motion and accurate positioning of the torch tower and tailstock along the length of the lathe. High precision servo driven rotation provides the required motion for a wide range of components from aerospace engine parts to end cap welding on metal hoses. Coupled with AMET’s advanced weld controls, the lathes are highly customizable and versatile. They are configurable for circumferential welding, OD cladding, and even longitudinal welding.

Welding Lathe Advantages

Versatility

These lathes are versatile. They can be used for a range of applications such as circumferentially welding end caps, cladding the outside of a part, welding additional components to the outside of parts such as stiffener rings, and longitudinal welds.

Compact/Self-Contained

The welding lathe is designed to be compact and self-contained. A workstation is included for mounting the headstock and tailstock, which also includes an equipment platform for the welding power supply and electronic components. This makes the system more organized while also minimizing trip hazards.

Precision Rotation

The precision rotation of the headstock and motorized torch lift provides controllable motion for performing single or multi-pass circumferential welds without additional setup or stopping in between passes.

GET A FREE QUOTE ON OUR CUSTOM WEldING LATHES

Custom Welding Lathe Machines

AMET Welding Lathes are produced in a full range of weld lengths and three different models, Precision Benchtop, Heavy-Duty Bench, and Industrial, to meet each of our customer’s specific application requirements.

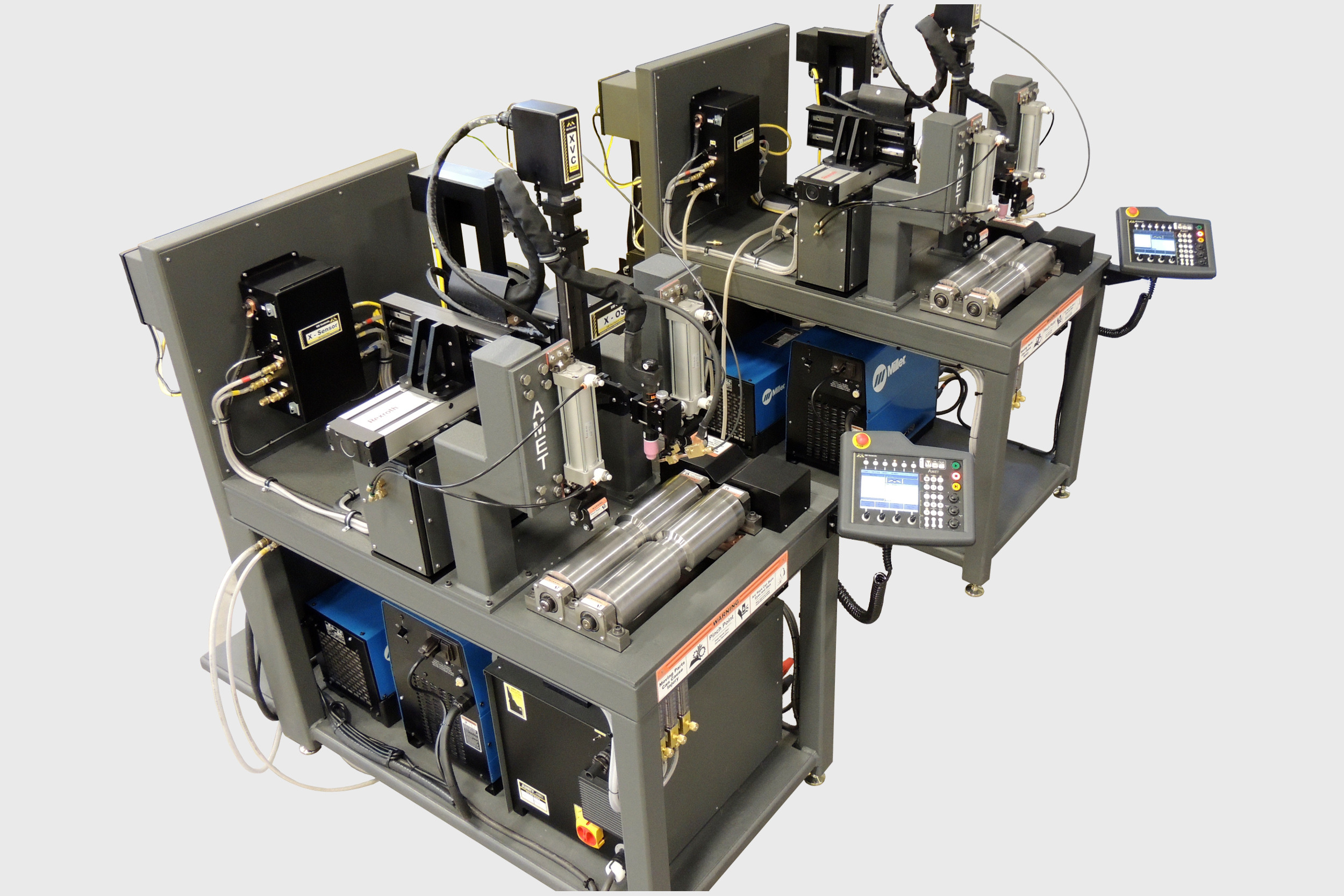

PRECISION BENCHTOP LATHE SYSTEMS

These Precision Lathe Welding Systems are designed and built for a high level of accuracy, versatility, and repeatability. They can be used for a wide range of applications with high or low production runs. With a small footprint, multiple lathes can be placed within a weld cell to optimize space and production.

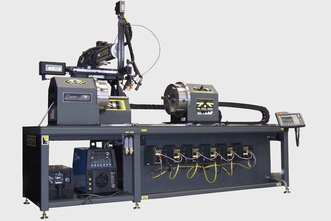

HEAVY-DUTY BENCH LATHE SYSTEMS

Like the Precision Benchtop Lathes, the Heavy-Duty Bench Lathes are designed and built for a high level of accuracy, versatility, and repeatability. These lathes simply have increased weight and part length capacities without sacrificing any of the precision motion.

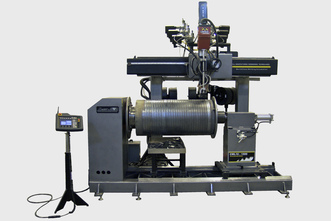

INDUSTRIAL WELD LATHE SYSTEMS

Industrial weld lathe systems are used to produce high quality welds with minimum distortion on circumferential (girth) weld joints for a wide variety of parts and part shapes. Single and multi-pass welding can be performed using GTAW, PAW, VPGTAW, VPPAW, GMAW, FCAW, or SAW welding. The weld lathe can be optionally fitted with two or more weld heads so multiple welds can be performed simultaneously.

TESTIMONIALS

AMET has been a great partner because they are appropriately positioned to act when we need a new solution engineered or need to service an existing solution. In the end the price of a solution is negligible if it works properly, and the vendor can keep it working through their service efforts. AMET knows these things and services their customers accordingly.

For over 15 years now I have had the privilege of working with AMET. I have personally seen how AMET Inc. industry knowledge and engineering expertise has enabled my business to increase weld quality and production and allow our clients to improve the strength and durability of their products.

AMET’s team is exceptional to work with. They look at the provided solution as a whole – from operator interfaces to engineering requirements, they seek to understand the customer’s needs throughout the project. This results in a welding system that is robust, embraced by the workforce, and meets the rigorous requirements of Blue Origin’s vehicles and engines. We’re excited to work with AMET on our vision of millions of people living and working in space.

FREQUENTLY ASKED QUESTIONS

What is a welding lathe?

Amet’s custom welding lathes are a machine that rotates a workpiece while a welding process is being carried out. These welding lathes offer accuracy, repeatability, and versatility for many applications. We integrate the lathes with chambers and glove boxes or they are pre-packaged with a workstation for a complete welding system.

What are the three types of welding lathes Amet inc offers?

Welding Lathes are produced in a full range of weld lengths and three different models, Precision Benchtop, Heavy-Duty Bench, and Industrial, to meet each of our customer’s specific application requirements.

What are the benefits of using a welding lathe?

Some of the benefits of using a custom welding lathe is versatility, compact, and precision rotation. This increases productivity because a separate program does not have to be loaded for each weld, and the torch does not have to be manually repositioned for each weld.

What factors should be considered when selecting a welding lathe?

When considering if you should get a custom welding lathe for your business, you should determine what material will be welded, size and weight of the workpiece, desired welding process, required welding speed, and the budget.

What industries can a welding lathe be used in?

At Amet Inc, we have worked with a variety of industries developing custom welding lathes. The industires includes construction, defense, food & beverage, oil & gas, power, and transportation.

Contact

Please call, write, or email our headquarters in Rexburg, Idaho for more information on how we can better serve you.

355 Dividend Dr

Rexburg, ID 83440