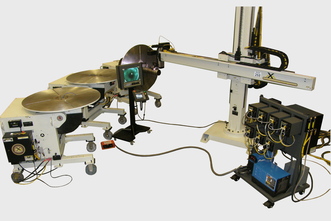

COLUMN AND BOOM MANIPULATOR SYSTEMS

At the core of these systems is AMET’s column & boom manipulators. AMET manipulators offer several distinct advantages over comparable products such as the use of precision hardened linear rails with recirculating ball bearings for motion, Acme Screw Column Lift drive that provides safe and stable lifting motion, and the fact that our manipulators are thermally stress relieved prior to fabrication. AMET manufactures a superior product that results in increased stability and rigidity at the weld head where stability, smooth motion, and rigidity are key to the weld result. AMET manipulators provide a level of precision and robustness that other motion components and designs are unable to match.

We offer a full line of part supporting equipment for these systems including turning rolls, turn tables, positioners, and travel carts. With our XM® or XPro Controller being able to integrate with and control the supporting equipment, we provide a seamless and complete welding system for virtually any application.

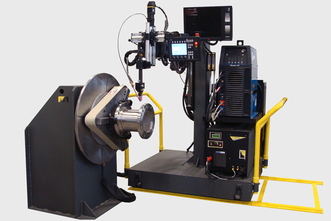

INTEGRATED PIPE SPOOL WELDING STATION

The GTAW Pipe Spool Welder is designed and built for joining pipes. With a clamping capacity range of 2 to 24 in (50 to 610 mm) OD, 1,000 lb (450 kg) capacity headstock, and 16 ft (4.9 m) of manual travel, throughput can be greatly increased with this automated welding system. Controls are easy to navigate, yet comprehensive. This system offers precision, strength, simplicity, and versatility, everything desired in a piping system.

Many weld processes, such as GTAW, PAW, GMAW, VPPAW, VPGTAW, and some SAW processes can be integrated on our column & boom manipulator systems. These systems are designed for many applications including hotwire bore cladding, vessel welding, flange welding, and part repairs. With our lines of part supporting and manipulating equipment that can be seamlessly integrated into the system, we can meet the needs of most projects.

COLUMN AND BOOM MANIPULATOR SYSTEMS (HEAVY DUTY)

BORE CLADDING SYSTEMS

Contact

Please call, write, or email our headquarters in Rexburg, Idaho for more information on how we can better serve you.

355 Dividend Dr

Rexburg, ID 83440