CONSTRUCTION

CONSTRUCTION

Construction welding automation requires adaptability to accommodate the wide range of products utilized for construction. AMET’s experience in this industry ranges from GTAW welding engine components for earth-moving equipment to multi-wire SAW thick section welding for bridge girders. AMET’s advanced controls are configurable for a wide range of welding processes, and we are able to integrate with third party components such as robots or other part loading equipment to support high volume production.

Our precision controls use high quality motion control components for each programmable axis. The axes are driven by encoder-based servo motors for precise motion and position control.

THE NEED

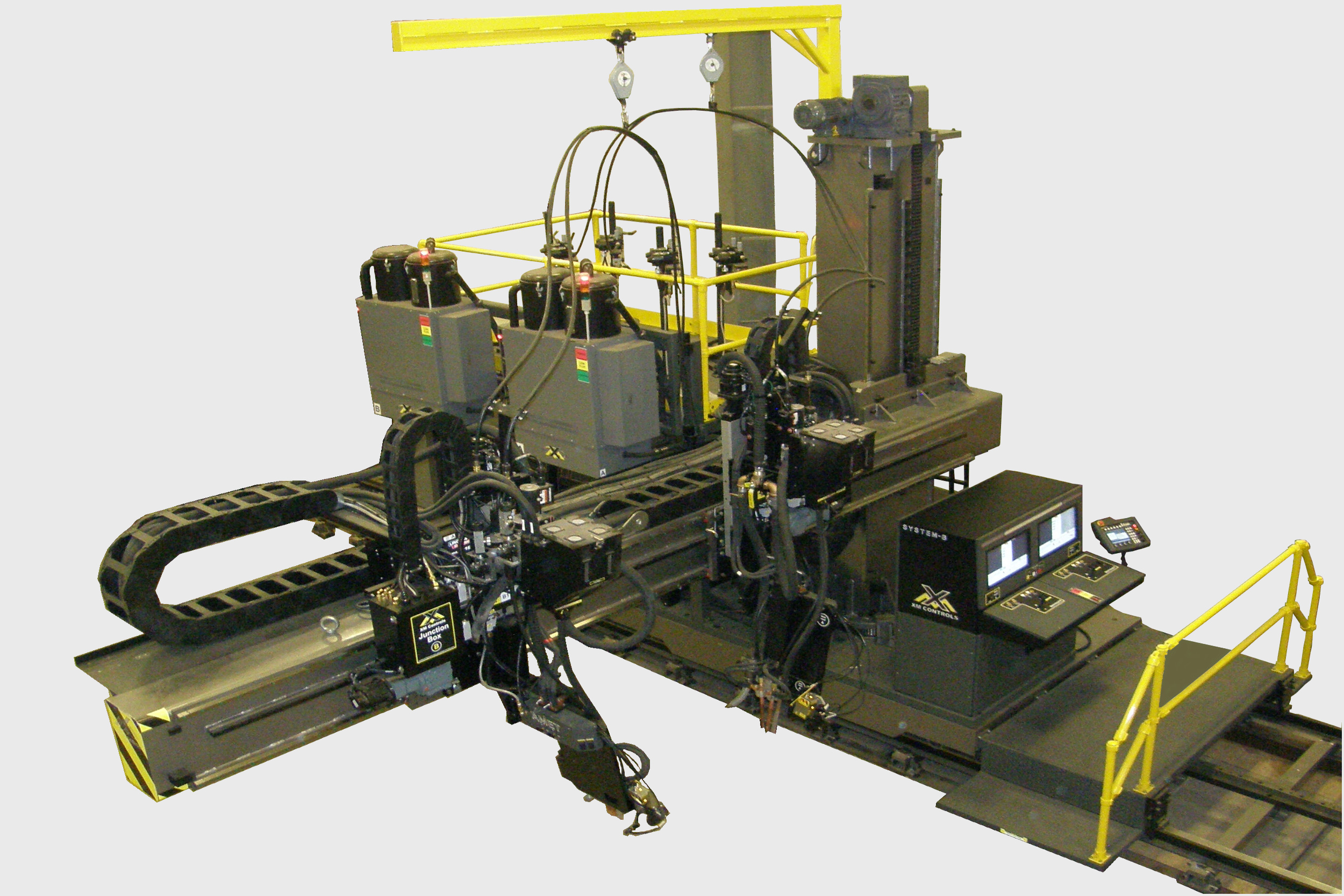

In some cases, heavy-duty part manipulating equipment is needed for the manufacturing of large components. Submerged arc welding is a common process for welding under these conditions. These applications can be single or multiple wire systems.

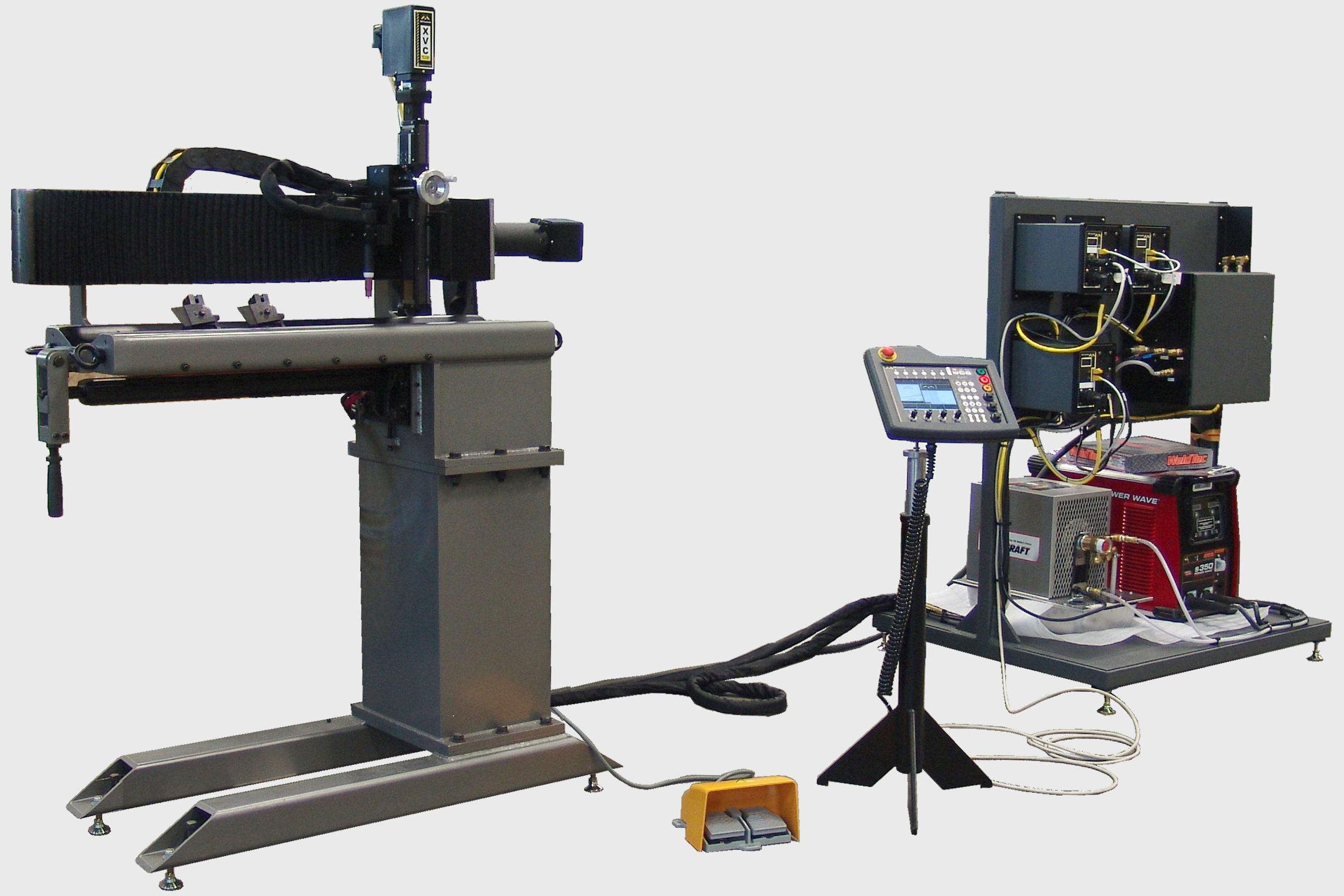

Precision high volume products are also common in this industry. Welding lathes and linear seam welders utilizing GTAW, GMAW, and PAW are an ideal solution for the production of precision high volume construction industry components.

SOLUTION

Our precision controls are designed to provide completely integrated construction welding automation. The precise nature and versatility of AMET controls allows operators to produce high volume parts with minimal variation or create custom weld programs for low volume production. Our controls are adaptable to suit the needs of virtually any application.

We manufacture complete lines of welding fixtures including manipulators, turning rolls, weld lathes, and linear seam welders. We build several SAW and GTAW solutions for construction welding automation including systems for metal hose production used for fire suppression, engine components used in the manufacturing of earth moving equipment, and heavy duty equipment used for road and bridge construction.

RESULT

Our systems are proven. We have over 20 specialized systems currently being used to produce high quality components for this industry. These systems have produced millions of parts.

Our systems are built for longevity. We produce all of our controls and software in- house, which allows us to provide years of service after the sale. Our ability to diagnose, repair, and service each system prevents obsolescence and provides a good return on investment.

One of our greatest strengths is our knowledgeable customer service department that will support each system expertly and courteously.

Contact

Please call, write, or email our headquarters in Rexburg, Idaho for more information on how we can better serve you.

355 Dividend Dr

Rexburg, ID 83440