OIL AND GAS

oil and gas

Usually performed in industrial environments, with high strength, and high quality weld requirements, welding applications for the Oil & Gas Industry can be challenging. AMET manufactures complete oil and gas welding automation systems with GMAW, SAW, Hot-Wire GTAW, or a combination of these processes for pipeline welding automation, valve and flange joining, vessel manufacturing, cladding and hardsurfacing, as well as for thick wall welding applications.

We specialize in advanced controls to provide the necessary capabilities from pipeline welding automation to complex bore cladding operations. Based on the performance of the numerous proven AMET® welding automation solutions for the Oil and Gas Industry, we believe we have the ability and experience to meet your project needs.

THE NEED

In this industry parts have to withstand highly corrosive and high-pressure environments, so quality and integrity are crucial. Precise controls and the ability to monitor welds are essential for producing high quality welds.

The Oil and Gas industry has many welding needs such as cladding, pipeline welding automation, and thick-wall welding.

Cladding for corrosion and abrasion resistance of sub-sea components is a common practice. Cladding requires precision motion and position control to ensure the required surfaces of each part are clad. This is a time consuming operation, so speed and wire deposition are also very important. Large or heavy parts or parts with non-cylindrical geometries can be extremely difficult to center on a turntable or positioner for cladding. These parts often have a lengthy setup time and also require heavy-duty rotation equipment and expensive tooling.

Pipeline welding automation, whether it is pipe-to-pipe welding or pipe-to-flange welding requires precision motion control for the rotation of the headstock or turning rolls. Pipe manufacturers commonly produce parts that vary greatly in length and diameter, so the ability to accommodate a range of sizes is important.

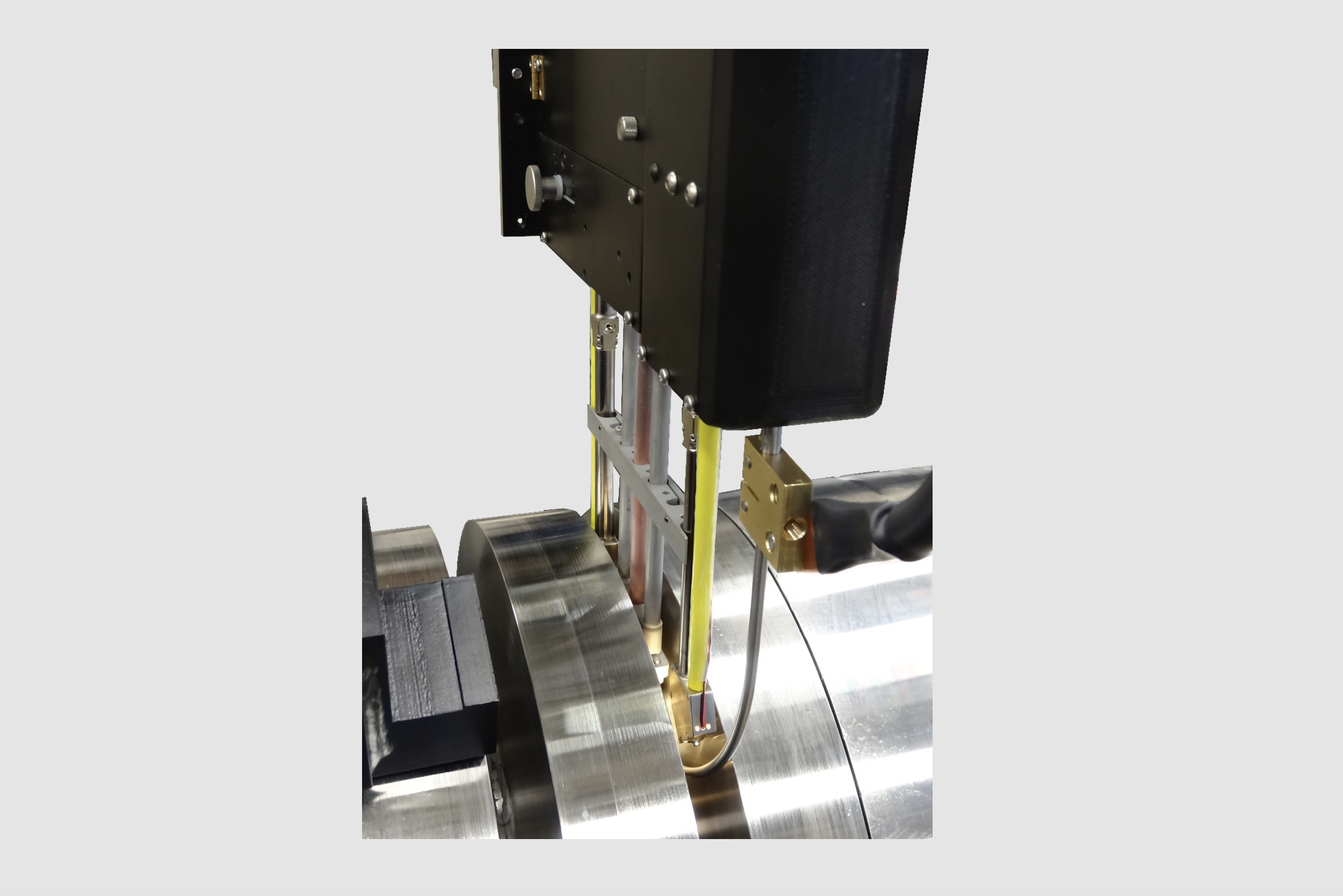

When performing thick-wall welding, one of the most important aspects is accurately placed beads with high deposition rates and speed. Often, multi wire or multi head processes are required to perform these welds more quickly and efficiently.

SOLUTION

Our precision controls are at the center of all of the solutions for the Oil & Gas Industry. Each system we produce is equipped with high quality motion and control components for reliable and consistent operation. Our systems are also capable of collecting data and monitoring the welds to ensure each part is welded as programmed. The collected data for each weld can then be exported and saved to a PC and printed for documentation purposes.

For very thick wall applications, AMET has developed Narrow Gap solutions. Our Narrow Gap weld heads for both GTAW and SAW welding increase throughput by decreasing the requisite joint angles on thick wall sections. These weldheads combined with the precision process control provide a solution that produces excellent results.

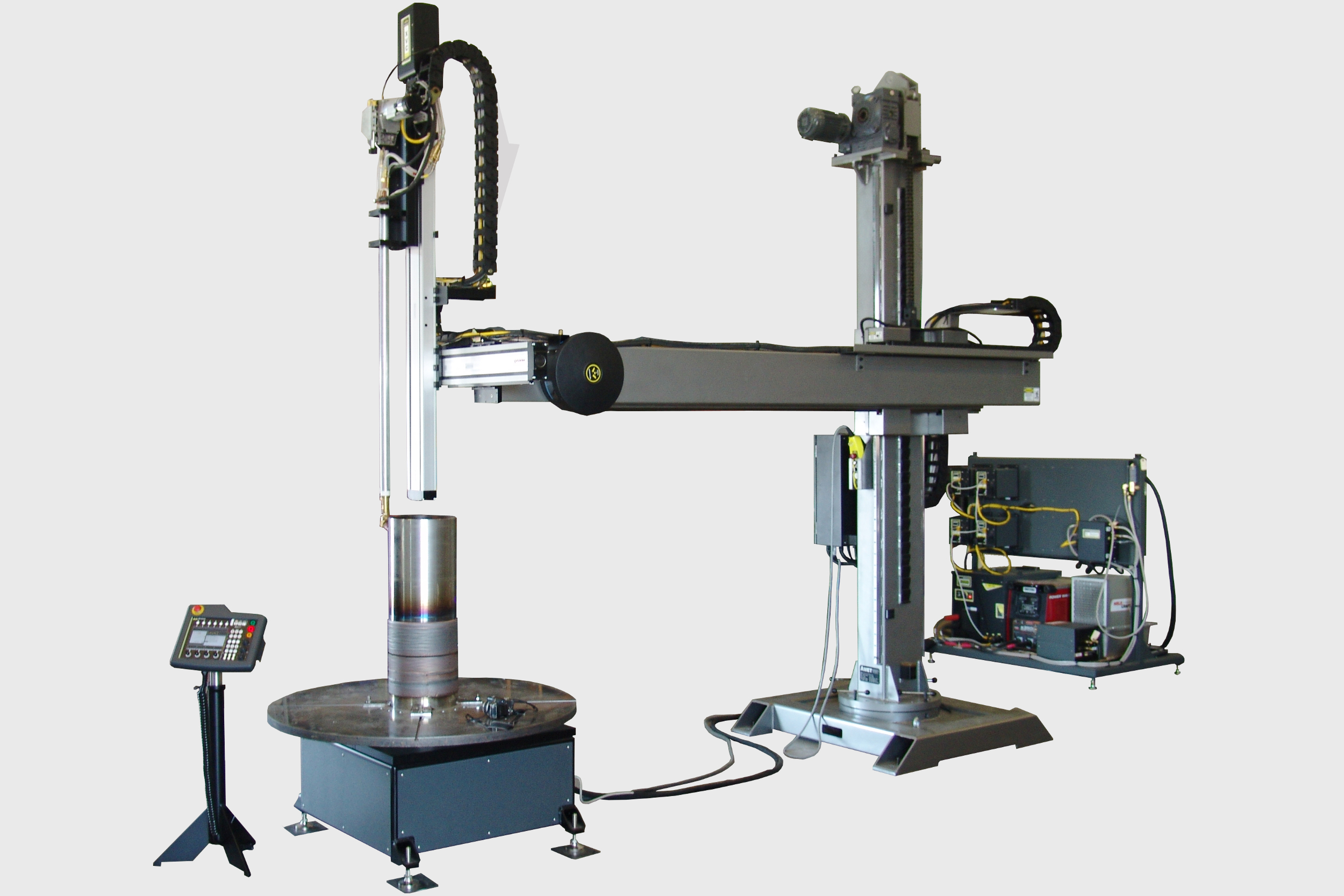

We offer several solutions for automating the cladding process from multi-wire cladding of the OD of pipes with a weld lathe to ID cladding using a bore cladding system. The Coordinated Motion Cladder (CMC-66) is ideally suited for cladding operations from simple to complex. The CMC is a unique solution that does not require expensive positioners to rotate the part, so costs and setup time are significantly reduced.

A wide variety of pipe diameters and lengths can be accommodated with AMET’s pipeline welding automation systems. Our full line of automated weld lathes and column and boom manipulator systems provide the necessary capabilities for both ID and OD applications.

Our extensive line of equipment when integrated with our XM Controller allows us to provide a solution for virtually any thick wall application. The XM is specifically designed to integrate with and control several processes and power supplies simultaneously. This helps increase deposition rates by integrating multi wire or multi process weld heads.

RESULT

We have proven systems that have been developed for narrow gap, cladding, and pipeline welding automation requirements. We have over 3 decades of experience with oil and gas welding automation and numerous systems currently being used to produce high quality components for this industry.

Our systems are built for longevity. We produce all of our controls and software in- house, which allows us to provide years of service after the sale. Our ability to diagnose, repair, and service each system prevents obsolescence and provides a good return on investment.

One of our greatest strengths is our knowledgeable customer service department that will support each system expertly and courteously.

Contact

Please call, write, or email our headquarters in Rexburg, Idaho for more information on how we can better serve you.

355 Dividend Dr

Rexburg, ID 83440