XM® WELDING CONTROLLER

the Industry’s preeminent welding controller

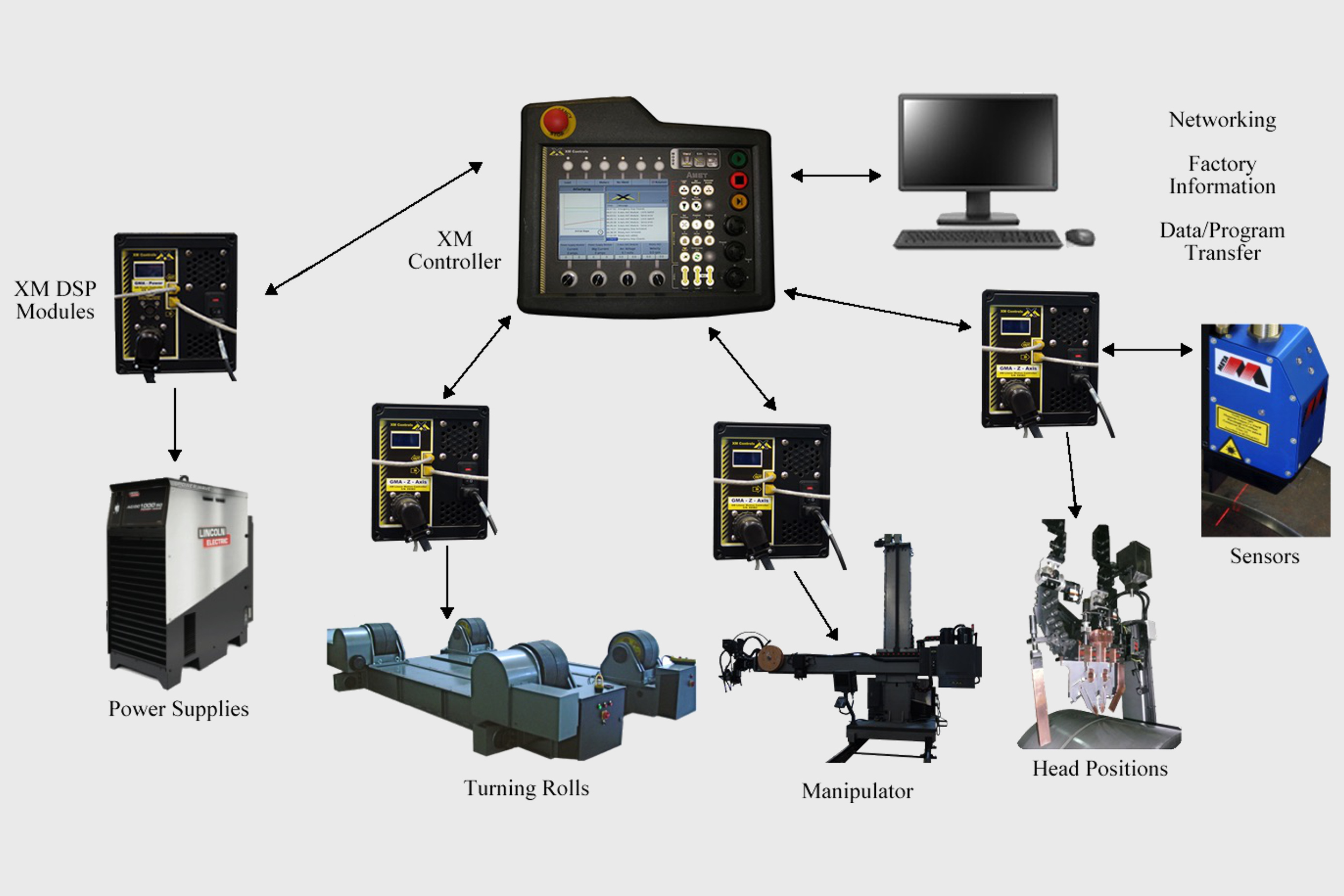

The XM® is AMET’s most proven Welding Controller. The networked architecture of the XM® Controller and the XM® control modules has been the foundation for more than 600 completely integrated welding systems for over a decade producing hundreds of thousands, or millions, of parts for prominent companies producing critical products. The versatility of the XM’s modular architecture, combined with the CAN Bus communication protocol, allows AMET® to provide some of the most robust and reliable welding automation solutions on the market.

The XM® features a unique user-friendly HMI (Human Machine Interface) for weld program creation and execution. Programming is performed using a combination of “select and dial” inputs and a graphical display. Simply select a parameter and dial in the desired value. The end result is an easy-to-program welding controller that does not require knowledge of any special machining languages.

30+ Years of welding Automation Excellence

The XM® Welding Controller is a very versatile weld process controller capable of meeting the needs of almost any weld process. The XM® has the following built-in capacities to effectively perform a large range of functions and welds:

- Units of Measurement: Capable of operating using Imperial or Metric units.

- Programs: Capable of storing 200+ weld programs. Weld programs can be saved and loaded directly from the Weld or Edit mode screens. Weld programs can be given specific names or numbers when saved such as part numbers or product names. Additional storage is available by inserting a USB flash drive and downloading files from one of the two USB ports located on the XM® Controller.

- Additional Languages: The XM® is capable of displaying menus in English, Spanish, French, Russian, Korean, and Chinese (partial)

- Modules: Up to 16 modules can be integrated into each XM® controller. Each module is equipped with an internal processor to share the computing load and prevent overworking the XM®.

- Equipment Capabilities: The combination of the XM® and the modules allows control over motion axes and power supplies.

- Weld Processes:

- GTAW (Gas Tungsten Arc Welding) or TIG

- GMAW (Gas Metal Arc Welding) or MIG

- SAW (Submerged Arc Welding)

- FCAW (Flux Cored Arc Welding)

- PAW (Plasma Arc Welding)

- VPPAW (Variable Polarity Plasma Arc Welding)

- VPGTAW (Variable Polarity Gas Tungsten Arc Welding)

The XM® Wedling Controller is a very powerful and capable weld controller. It offers the following advantages over the competition’s controllers and non-automated welding systems:

- The XM® Welding Controller utilizes Linux, which ensures that AMET® will be able to provide long-term support and stability. AMET® writes the XM® software, so there is no risk of the XM® becoming obsolete due to third-party software changes.

- Expandable for future needs. The XM® Welding Controller features “Plug and Weld” modules that allow increased system capabilities by simply plugging in a new module. When a new module is introduced into the system, the XM® automatically recognizes it and integrates it into the system.

- Easy-to-use interface. Welding Controller programs can be created, edited and run by a combination of the buttons and programming knobs. The intuitive layout makes it easy to program each segment in an organized and sequential manner.

- Overrides for all axes and parameters are possible during welds. The operator can make adjustments to account for variations in the materials and weld joints.

- A supervisor or welding engineer can create the welding programs and then set override limits to prevent the operator changing parameters too much. These limits can be protected, to ensure that only those with certain access can make changes.

- A sensor box can be integrated into the system to monitor water flow for water-cooled torches or other components. If water flow is not detected the XM® displays an alert to help prevent damage to the water-cooled components. Gas flow is also monitored and reported in a similar manner to help ensure cover gases are in the weld zone to maintain welding integrity.

The XM® Welding Controller is a very powerful weld process controller. It is capable of integrating with and controlling the following equipment:

- Welding Power Supply: The XM® is capable of controlling all weld parameters of several brands and types of welding power supplies.

- Arc Voltage Control (AVC): The AVC provides constant arc standoff and also allows for touch starts and touch retract.

- Cold Wire Feed Control: Wire feed speeds and wire retract are programmable.

- Hotwire Feed Control: Wire feed speeds and voltage to the wire before it enters the weld puddle are programmable.

- Linear Travel Control (horizontal and vertical): Motion is programmable by distance, speed, or time.

- Oscillation Control:

- Mechanical Oscillation: Dwell time and oscillation distance are programmable.

- Magnetic Oscillation: Programmable control of slew time, dwell time, amplitude, and arc position. The arc can be deflected and maintained in a set position to aid in certain types of welding such as fillet welding.

- Rotation control: Motion can be programmed by RPM, degrees of rotation, or time. Continuous and manual (jogging) rotation are also available on the XM® Welding Controller.

- Gas Flow: Soft button to Enable/Disable located on XM®.

Testimonials

Great Partner

"AMET has been a great partner because they are appropriately positioned to act when we need a new solution engineered or need to service an existing solution. In the end the price of a solution is negligible if it works properly, and the vendor can keep it working through their service efforts. AMET knows these things and services their customers accordingly."

- Matrix Drilling Products

15+ Years

"For over 15 years now I have had the privilege of working with AMET. I have personally seen how AMET Inc. industry knowledge and engineering expertise has enabled my business to increase weld quality and production and allow our clients to improve the strength and durability of their products."

- G. Wright's Welding Ltd.

Exceptional Team

"AMET’s team is exceptional to work with. They look at the provided solution as a whole – from operator interfaces to engineering requirements, they seek to understand the customer’s needs throughout the project. This results in a welding system that is robust, embraced by the workforce, and meets the rigorous requirements of Blue Origin’s vehicles and engines. We’re excited to work with AMET on our vision of millions of people living and working in space."

- Blue Origin

1 The Emergency Stop (E-Stop) button immediately terminates the weld program, stops weld current output from the power supply, and ceases all servo-controlled motion..

1 The Emergency Stop (E-Stop) button immediately terminates the weld program, stops weld current output from the power supply, and ceases all servo-controlled motion..

2 The six soft buttons each have a corresponding function that is displayed on the LCD screen. The functions change based on the selected Mode, which allows several functions to be performed by each button, streamlining the user interface.

3 The Mode buttons (Weld, Edit, and Setup) put the welding controller into its corresponding mode of operation. System settings are accessed in Setup Mode, weld programs are built or edited in Edit Mode, and weld programs are executed in Weld Mode.

4 The Sequence buttons (Start, Stop, and Advance) are used during weld program operation. The Start button activates the weld program. The Stop button extinguishes the arc, stops all motion, and advances to the downslope segment of the program. The operator must press the Advance button before proceeding to the next task or weld segment. The Advance feature allows for a pause or a continuous function to be included in the weld program.

5 The Function buttons enable or disable weld process specific functions such as gas flow, AVC, flux delivery, laser seam tracking, etc. These buttons also provide jogging and homing motion control for motorized axes.

6 Three joysticks are included to control up to six motion axes. The joystick control has a proportional feature, meaning, the farther the physical joystick is moved along its throw, the faster the axis it commands will travel.

7 The four encoder pots are used for “select and dial” programming. The encoder pots allow you to scroll through a list of functions by rotating the knob and then selecting the desired function by pressing down on the knob. After the function is selected, simply rotate the knob to dial in the desired value. The pots include tactile feedback with a detent for each incremental rotation, which allows the operator the ability to make override adjustments by feel without looking away from the weld.

8 One Ethernet and two USB ports are included for transferring weld programs and weld data files to and from external devices and networks. For example, flash drives can be plugged in to the USB ports for uploading or downloading weld programs. These connections are located on the backside of the XM®.

AUTOMATION

AUTOMATION

A critical part of the allure of XM® Controls is the ability to automate functions in the welding process. The system may be set up to enable laser tracking, start part rotation when the weld commences, and even load and unload a part. Up to 20 pre-weld and 20 post-weld operations can be programmed into each weld program.

LOCALIZATION SOFTWARE

LOCALIZATION SOFTWARE

The XM® and XPro screens can be displayed with languages other than English. Spanish, Korean, Russian, French and Chinese (Partial) are available. Other languages may require fees for translation costs.

DATA ACQUISITION AND TOLERANCE CHECKING SOFTWARE

DATA ACQUISITION AND TOLERANCE CHECKING SOFTWARE

Data is collected and analyzed in real-time to ensure all modules are within the set tolerances. The data points can be displayed graphically on the display and can also be exported as a .csv file and viewed on a program such as Microsoft Excel. These files can be exported through one of the USB or Ethernet ports on the XM® or XPro Controller.

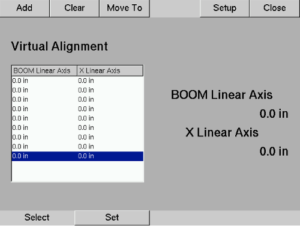

VIRTUAL ALIGNMENT (TEACHING MODE)

VIRTUAL ALIGNMENT (TEACHING MODE)

The operator can “teach” a weld path by manually moving the weld torch along the seam and selecting points. Up to 20 points can be selected to create a circumferential, longitudinal, or combination weld path. After all of the desired points are selected, the system will retrace each one to create a custom weld path. This can be helpful if parts or materials vary or have unique joint configurations. The path can be repeated for multiple pass welds, or offsets can be applied to repeat the motions of the original path in a new location.

Useful Links and Information:

Links

Contact

Please call, write, or email our headquarters in Rexburg, Idaho for more information on how we can better serve you.

355 Dividend Dr

Rexburg, ID 83440