ARC WELDING CAMERA SYSTEMS

Superior Arc viewing technology

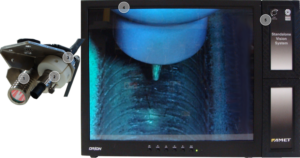

The AMET X-View arc welding camera systems represent a significant advancement in arc viewing technology. What makes our camera systems unique is the way the image is processed.

The optical section of the camera head consists of materials that “block” specific light frequencies. Other filters reduce high light levels in specific regions of the image, such as around the arc.

Once optically treated, the image is sent to the video sensor and converted to an electronic signal and then sent to the video controller. The video controller scans each frame in real-time using proprietary firmware running on a dedicated video processor. The frame-by-frame analysis is used to continually adjust shutter speed, gain, and color balance, resulting in consistent light levels and excellent detail throughout the entire picture.

AMET camera packages are available as an integrated component of a system.

30+ Years of welding Automation Excellence

AMET’s advanced Arc Welding Camera Systems offer the following capabilities and functions:

Camera Head:

- Focus: Manually adjustable by turning lens barrel. A nylon set screw is included to lock the barrel in place once focus is set.

- Recommended Weld Processes: GTAW and PAW

- Nominal Focus Distance: 6 in (152 mm) from arc

- Nominal View Angle: 45 degrees from weld plane

- Field of View: 1.25 in (32 mm) measured diagonally

- Operating Temperature Rating: 125° F (52° C) maximum temperature at sensor

- Cooling Method: Air-cooled

Illuminator:

- Light Source: High intensity LEDs or a halogen bulb, depending on the application, illuminate field of view

- Light Sensor: Infrared detector automatically powers off illuminator when arc is present.

Arc Video Controller:

- Video Output: 4:3 NTSC Color

- Image Brightness: Adjustable through potentiometer

The X-View Arc Welding Camera Systems offer the following advantages:

- Compatibility: The video processor converts the images into standard NTSC video format that can be viewed on most monitors. This also eliminates the need for a computer to perform video conversion.

- Compact Size: Does not add excess bulk to weld head.

- Simple Operation: Easy-to-use controls with the ability to select the optical viewing orientation.

- Longevity: There are no moving parts so the possibility of failure is reduced. Lens shield is replaceable, and an inert gas purge channel is also included to protect the window from being contaminated by welding vapors.

- Lighting: An illuminator is integrated into the camera system with an infrared detecting sensor. The light is automatically switched off when an arc is present to provide ideal lighting for both arc-on and arc-off conditions. The sensor also helps increase the life of the illuminator by switching it off during welding.

- Well Insulated: The camera resists interference from high-frequency arc starters.

Due to the sophisticated nature of the X-View Ar Welding Camera Systems, there is very little adjustment or manual control necessary. The majority of the adjustments are automatically controlled by our proprietary firmware, but there are a few manual adjustments. The automatic and manual functions are listed below.

Automatically Controlled Functions:

- Dividing individual images into regions to provide a more balanced and consistent video image. Each of the following are controlled in real-time for each region:

- Shutter speed

- Color balance

- Reduction of high light levels

- Converting the video image into an NTSC analog format

Manually Controlled Functions:

- Focus – Adjustable by rotating lens barrel

- Light Intensity – Brightness level is adjustable

- On/Off Control – The camera includes an on/off control switch

Testimonials

Great Partner

"AMET has been a great partner because they are appropriately positioned to act when we need a new solution engineered or need to service an existing solution. In the end the price of a solution is negligible if it works properly, and the vendor can keep it working through their service efforts. AMET knows these things and services their customers accordingly."

- Matrix Drilling Products

15+ Years

"For over 15 years now I have had the privilege of working with AMET. I have personally seen how AMET Inc. industry knowledge and engineering expertise has enabled my business to increase weld quality and production and allow our clients to improve the strength and durability of their products."

- G. Wright's Welding Ltd.

Exceptional Team

"AMET’s team is exceptional to work with. They look at the provided solution as a whole – from operator interfaces to engineering requirements, they seek to understand the customer’s needs throughout the project. This results in a welding system that is robust, embraced by the workforce, and meets the rigorous requirements of Blue Origin’s vehicles and engines. We’re excited to work with AMET on our vision of millions of people living and working in space."

- Blue Origin

1. The integrated illuminator provides the necessary lighting for arc-off conditions. The light consists of bright LEDs or a halogen bulb to ensure the optimal image display in low-light conditions. The light aids in positioning the weld head during setup.

2. The arc welding camera body features a replaceable lens shield with manual focus adjustment and a set screw to prevent unwanted movement. Brackets for mounting the light source and camera body to the welding torch are included. The brackets are compatible with most TIG and Plasma machine torches.

3. A switch is located on the back of the camera body to activate a spot filter, which aids in proper camera positioning and filters excess light during welding. Alignment of the spot filter is done by moving the camera body so the top of the filter covers the bottom portion of the electrode. When the arc is ignited, the spot is automatically activated by the photo-sensor. The attenuation level of the spot filter is adjustable through a potentiometer.

4. A video module performs all of the necessary functions to automatically filter light, adjust shutter speed, adjust gain, and adjust color balance.

5. The monitor provides a high-resolution display of the video feed from the camera. The monitor also houses a potentiometer to adjust the light intensity from the light source.

WATER-COOLED CAMERA

WATER-COOLED CAMERA

The standard air-cooled camera configuration can be upgraded to a water-cooled version. This includes a water jacket surrounding the camera body. Cooling is achieved using a water circulator just like water-cooled torches.

ANGLED VIEWING OPTIONS

Our standard camera viewing angle is setup to be 45 degrees from the weld plane. In some cases, the fixturing or space constraints require the camera to be oriented at a different angled. We offer various configurations, so please contact us with your project specifications.

CUSTOM FOCAL LENGTHS AND FIELDS OF VIEW

AMET® offers custom focal lengths and fields of view for the camera. Contact us to discuss the needs for your application.

Useful Links and Information:

Links

Contact

Please call, write, or email our headquarters in Rexburg, Idaho for more information on how we can better serve you.

355 Dividend Dr

Rexburg, ID 83440