RETROFITS

Bringing new technology to an old workhorse

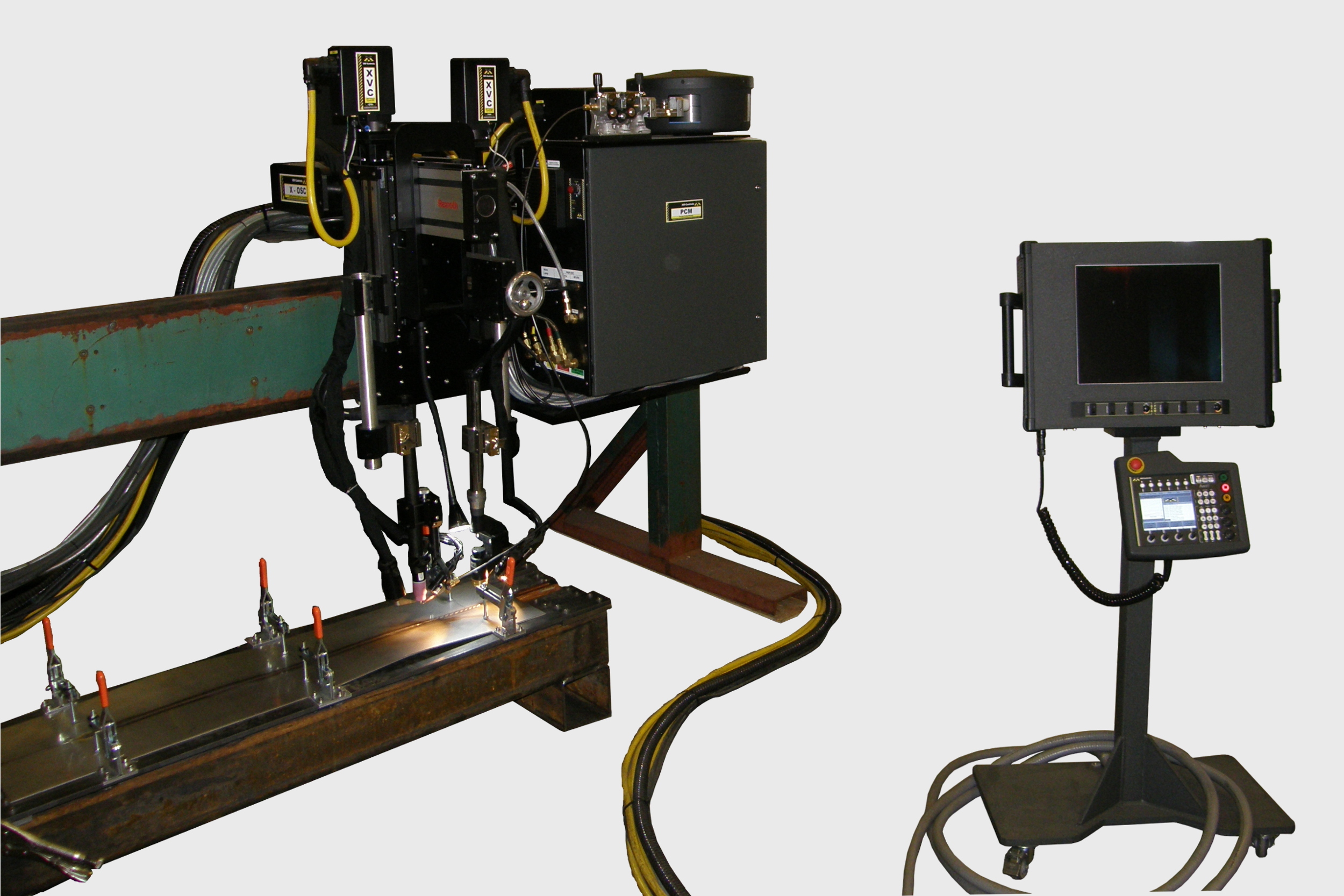

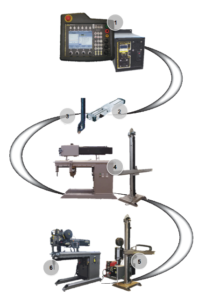

Retrofits typically consist of a complete replacement of the controls and motion axes of systems produced by other manufacturers. We retrofit manipulator, linear seam welder, weld lathe, and bore cladding systems as long as the fixturing is functioning adequately, and consistent with AMET’s control needs.

A Retrofit consists of replacing all of the control components including servo motors, amplifiers, and encoders. This ensures compatibility with the XM® or XPro Weld Control architecture when integrating with other manufacturer’s fixturing. A common retrofit integrates multiple weld processes such as Plasma and TIG or MIG and Subarc to increase versatility and capability.

Retrofits are performed at the AMET® facility in Rexburg, ID to integrate and test all components. Often, we require the existing weld fixtures on-site at our facility for integration, but in some cases, we create temporary fixtures for testing and assembly. The new controls and motion axes are then integrated and installed at the client’s facility.

30+ Years of welding Automation Excellence

AMET® offers the following capacities when retrofitting automated welding systems:

- Weld Head Motion (Vertical and Horizontal):

- Motorized Motion: Servo motor driven precision slides with programmable motion in increments of 0.001 in (0.025 mm). The slides are available in a wide variety with a range of motion from 2 to 60 in (51 to 1524 mm).

- Manual Motion: Hand crank slide with 6 in (152 mm) of motion. Additional sizes available upon request.

- Pneumatic Motion: Air-driven slide with 6 in (152 mm) of motion. Activation can be controlled by weld program. Additional sizes available upon request.

- Rotary Motion: Programmable in increments of 0.1 degree and by speed (RPMs). Speed is dependent upon drive assembly components of rotary device.

- Linear Motion: Upgrades to linear motion axes such as carriages on seam welders or booms on manipulators. These upgrades include servo motors with encoder feedback to provide programmable motion by distance or speed. Speed and distance capacities are dependent upon existing equipment setup and capabilities.

- Power Supplies: AMET® is capable of integrating multiple arcs into one system. We offer TIG & Plasma, MIG and Subarc, and Multiple Wire Subarc. We also integrate other combinations of these processes. Contact us with your specifications.

AMET® Retrofits are a cost-effective way to renew existing equipment such as lathes, manipulators, or seam welders. Our extensive experience performing retrofits and our advanced control packages provide an excellent upgrade option with the following advantages:

- Retrofits are possible with most welding fixture manufacturer equipment. AMET® integrates with manipulators, seam welders, lathes, positioners, and cladders. Additional fixtures are also possible. Please contact us regarding custom or specialized equipment.

- Older equipment is refreshed and updated with advanced weld process controllers. Precision and accuracy can be renewed to the original state or possibly upgraded to a higher level of precision, extending the service life of the equipment.

- Retrofits cost less than a completely new system, yet still offer the same level of advanced controls and integration that AMET® provides on new systems, providing a high return on investment.

- Our advanced and versatile controls allow multiple arcs or processes to be integrated into a single system. Our engineers design and create the necessary brackets and motion components for integrating multiple arcs or processes into a single weld head. This level of flexibility offers efficiency and a capacity for welding a wider range of products without the need of multiple systems.

The XM® and XPro Controllers are very powerful weld controllers, and are at the center of each retrofit. They are capable of integrating with and controlling the following equipment:

- Welding Power Supply: Capable of controlling all weld parameters of several brands and types of welding power supplies.

- Arc Voltage Control (AVC): The AVC provides constant arc standoff and also allows for touch starts and touch retract.

- Cold Wire Feed Control: Wire feed speeds and wire retract are programmable.

- Hotwire Feed Control: Wire feed speeds and voltage to the wire before it enters the weld puddle are programmable.

- Linear Travel Control (horizontal and vertical): Motion is programmable by distance, speed, or time.

- Oscillation Control:

- Mechanical Oscillation: Dwell time and oscillation distance are programmable.

- Magnetic Oscillation: Programmable control of slew time, dwell time, amplitude, and arc position. The arc can be deflected and maintained in a set position to aid in certain types of welding such as fillet welding.

- Rotation control: Motion can be programmed by RPM, degrees of rotation, or time. Continuous and manual (jogging) rotation are also available on the XM® and XPro Controllers.

- Gas Control: Manual flow meters and a gas solenoid provide a constant gas flow rate. A soft button activates gas at the default flow rate until the button is deactivated or until the end of the weld program.

Testimonials

Great Partner

"AMET has been a great partner because they are appropriately positioned to act when we need a new solution engineered or need to service an existing solution. In the end the price of a solution is negligible if it works properly, and the vendor can keep it working through their service efforts. AMET knows these things and services their customers accordingly."

- Matrix Drilling Products

15+ Years

"For over 15 years now I have had the privilege of working with AMET. I have personally seen how AMET Inc. industry knowledge and engineering expertise has enabled my business to increase weld quality and production and allow our clients to improve the strength and durability of their products."

- G. Wright's Welding Ltd.

Exceptional Team

"AMET’s team is exceptional to work with. They look at the provided solution as a whole – from operator interfaces to engineering requirements, they seek to understand the customer’s needs throughout the project. This results in a welding system that is robust, embraced by the workforce, and meets the rigorous requirements of Blue Origin’s vehicles and engines. We’re excited to work with AMET on our vision of millions of people living and working in space."

- Blue Origin

1. AMET® Automated Welding System Control Retrofits. The architecture used in AMET’s controls allow us to accommodate a wide range of power supplies, fixturing, safety, and automation equipment. The controls are designed and built in house to seamlessly integrate with existing equipment.

2. Precision and Manual Motion Axes. AMET® produces and integrates motion axes and the necessary bracketry for vertical and horizontal weld head movement. The precision axes consist of servo motor driven components with encoder feedback for programmable motion and position. Manual axes are hand crank driven slides with manual brakes to prevent movement during welding operations.

3. Testing. AMET® control components are produced in house, which allows us control over the quality and the ability to test each component as it is produced. This includes individual components such as control boards and complete assemblies like control modules and the XM® and XPro Controllers. Each component and assembly is rigorously tested, as is the whole system to ensure proper functionality, compatibility and longevity.

4. Fixturing. AMET® performs Automated Welding System Control Retrofits on manipulator, seam welder, lathe, positioner, and cladding fixturing made by virtually any manufacturer. The fixturing can be new or used as long as it is functioning adequately at the beginning of the retrofit process.

5. Integration. The controls and motion components are integrated with the fixturing for performing hard automation welds. The advantage to AMET® Automated Welding System Control Retrofits is that we design the software and hardware of our controls to seamlessly integrate with each fixture. This holistic approach ensures compatibility with virtually any weld fixture.

6. Complete System. AMET® provides complete systems with a warranty on all AMET® produced components. Upon completion of testing and integration at the AMET® facility in Idaho, we setup and install the retrofit system onsite at the client’s facility.

INTERSECTING BORE CLADDING CAPABILITY

INTERSECTING BORE CLADDING CAPABILITY

Intersecting bore location and size can be programmed through the XM® or XPro Controller. During cladding, the arc will automatically be extinguished when the torch reaches the edge of the intersecting bore and then reignite once it reaches the other side. This will be repeated until the system has clad around the entire intersecting bore and then continuous cladding will resume. Bores must intersect the main part at an angle perpendicular to the center.

CAMERA SYSTEM (SAW)

CAMERA SYSTEM (SAW)

A video camera and cross-hair laser generator are mounted to the weld head to aid in monitoring during welding operations. The video feed is displayed in real-time on the operator console monitor. The camera is also used to aid in positioning the torch(es) during setup.

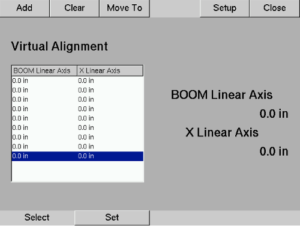

VIRTUAL ALIGNMENT (TEACHING MODE)

VIRTUAL ALIGNMENT (TEACHING MODE)

The operator can “teach” a weld path by manually moving the weld torch along the seam and selecting points. Up to 20 points can be selected to create a circumferential, longitudinal, or combination weld path. After all of the desired points are selected, the system will retrace each one to create a custom weld path. This can be helpful if parts or materials vary or have unique joint configurations. The path can be repeated for multiple pass welds, or offsets can be applied to repeat the motions of the original path in a new location.

MECHANICAL OSCILLATION

MECHANICAL OSCILLATION

A precision servo motor driven ball screw slide with encoder feedback provides mechanical oscillation. The oscillation motion is completely programmable including dwell time, oscillation frequency and width, and travel speed.

OFFLINE PROGRAMMING SOFTWARE

OFFLINE PROGRAMMING SOFTWARE

Weld programs can be created, modified, or stored on a PC. These programs can be moved back and forth between the controller and the PC using a USB storage device or through an Ethernet connection. This software can increase productivity by allowing programs to be created/edited while the weld controller is executing another weld program.

PLC CONTROLS

PLC CONTROLS

We integrate components into our controls for automating additional functions other than the welding process. These components include safety equipment such as automatic weld screens or curtains that are programmable to automatically open and close at the end or beginning of each weld. We can also integrate additional tooling such as automated part loading equipment.

FLUX DELIVERY AND RECOVERY SYSTEM

FLUX DELIVERY AND RECOVERY SYSTEM

The entire system is air-pressurized and heated to provide continuous flux delivery and recovers unused flux to help reduce costs. The system consists of a feed tank, delivery and recovery unit with 5 HP vacuum, and hopper for delivery at the weld head. The hopper is equipped with a valve to allow the operator to control the ratio of new and recovered flux delivered at the weld head.

MAGNETIC OSCILLATION

MAGNETIC OSCILLATION

Magnetic probe is used to deflect the arc back and forth in a stirring motion for excellent sidewall tie in. The arc can also be deflected and maintained in a set position. This can be beneficial for fillet or otherwise hard-to-reach joints. Dwell time, oscillation frequency, and width are all programmable from AMET® controls. Compatible with both magnetic and non-magnetic materials.

AUTOMATION

AUTOMATION

A critical part of the allure of XM® Controls is the ability to automate functions in the welding process. The system may be set up to enable laser tracking, start part rotation when the weld commences, and even load and unload a part. Up to 20 pre-weld and 20 post-weld operations can be programmed into each weld program.

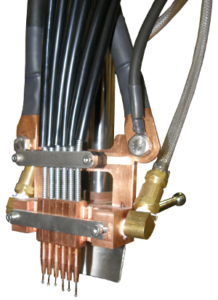

MULTIPLE PROCESS WELD HEAD

MULTIPLE PROCESS WELD HEAD

Our advanced controls allow us to integrate multiple weld processes into one weld head. Each process can be operated independently or simultaneously. For example, a TIG & Plasma weld head would feature two AVC axes (one for each torch) and either torch could operate or they can both operate simultaneously for Keyhole Plasma with a TIG trail. We offer TIG & Plasma, TIG & MIG, TIG MIG & Plasma, and SAW & MIG. Any of these combinations are available and would be completely programmable from ONE central controller. Other combinations are also available. Please contact us with any requests.

TURN TABLE

TURN TABLE

AMET® manufactures a full line of high precision turn tables with weight capacities from 550 to 22,100 lb (250 to 10000 kg). We also offer standard version turn tables with weight capacities from 2,200 to 132,200 lb (1000 to 60,000 kg). Each turn table faceplate includes a thru-hole for a gas purge device.

SPIRAL PATH AND STEP-INDEX CLADDING

SPIRAL PATH AND STEP-INDEX CLADDING

The vertical or horizontal axis is integrated with the rotary axis to provide precise cladding motion. We offer both Spiral Path, and Step-Index cladding options. Spiral welds begin at the bottom of the part and spiral upward until the defined height is reached. Step-Index clads in a straight line for each revolution of the part. After each revolution is completed, the torch steps upward and begins the next pass. The pitch of the spiral and the step height are programmable.

ARC VIEWING CAMERA

ARC VIEWING CAMERA

Arc Viewing Cameras can be added to a GTAW/PAW system giving the operator a view of the weld arc from a remote location. This keeps the operator in a safe location and reduces operator stress and fatigue. Additionally, the image that is shown on the monitor is magnified and shows greater detail than what could be observed without the camera. Multiple cameras may be integrated for projects where a view of the lead and trail side of the weld zone is required. Please see the Arc Viewing Camera page for additional information.

DATA ACQUISITION AND TOLERANCE CHECKING SOFTWARE

DATA ACQUISITION AND TOLERANCE CHECKING SOFTWARE

Data is collected and analyzed in real-time to ensure all modules are within the set tolerances. The data points can be displayed graphically on the display and can also be exported as a .csv file and viewed on a program such as Microsoft Excel. These files can be exported through one of the USB or Ethernet ports on the XM® or XPro Controller.

MULTIPLE WIRE WELD HEAD

MULTIPLE WIRE WELD HEAD

AMET® specializes in offering custom weld heads. We offer GTAW and PAW weld heads with two wires. The wire feeders can be synced to operate simultaneously or they can be separated to operate independently. We also offer multiple wire SAW head welds. Up to 10 wire weld heads can be integrated with our control packages for applications such as cladding. Tandem or triple wire weld heads are also available for thick wall welding applications.

POSITIONERS

POSITIONERS

AMET® manufactures a wide range of positioners with weight capacities from 550 to 22,000 lb (250 to 10000 kg). They feature 135 degrees of motorized tilting and continuous motorized rotation. The rotation axis can be integrated with the XM® or XPro to provide programmable control for welding operations. High-precision models are also available with harmonic drive rotation for the most stringent needs. The standard configurations include a fixed base, but an elevating base is also available. Each positioner includes a thru-hole for a gas purge device.

COMPLEX INTERSECTING BORE CLADDING

Includes all of the features from the Intersecting Bore Cladding option with the addition of automatically cladding bores at off-center and off-angle intersections.

MONITORING SENSORS

AMET® offers several sensors to monitor several functions and aspects of the weld. Each one of these sensors can automatically terminate the weld program if levels exceed the set parameters. The following sensors are available:

• Humidity Sensors – measures humidity levels at the weld puddle

• Oxygen Sensors – measures oxygen levels at the weld puddle

• Water Sensors – monitors water flow for components such as torches

• Gas Sensors – monitors gas flow for shielding/backing/purging gas

PROGRAMMABLE GAS CONTROL

Adds programmable gas flow control for GTAW and PAW applications.

LASER SEAM TRACKING

LASER SEAM TRACKING

The XM® or XPro integrate with a laser sensor to scan and track the weld joint during welding. The laser continuously scans the joint profile and makes the necessary adjustments to ensure the torch maintains the programmed location. The scanned profile is also displayed in real-time on the operator console monitor. Seam tracking can be configured for single or multi-pass welds.

SINGLE POINT POWER DISTRIBUTION

SINGLE POINT POWER DISTRIBUTION

AMET® provides fuse-protected power to all system components from a single primary power circuit (provided by customer).

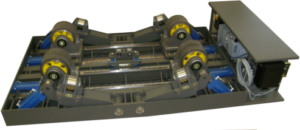

FIT-UP STATION

FIT-UP STATION

AMET® manufactures fit-up stations for aligning two sections prior to welding. The fit-up stations feature four (4) wheels that are controlled hydraulically. The wheels are divided into pairs A & B and C & D, and there are several options for moving them to accommodate a wide range of applications. The following motions are possible: each wheel can be moved independently (in/out from the centerline), each pair can be moved simultaneously (in/out or side-to-side), or all four wheels can be moved simultaneously. The fit-up station can also be mounted on a rail system and have motorized motion in a growing line system.

INTEGRATED PURGE/BACKING GAS

INTEGRATED PURGE/BACKING GAS

This package includes a gas union, digital solenoid, manual flow meter, and a gas line from the solenoid to the gas union for purging or backing gas capability. The digital solenoid is integrated with the XM® and XPro Controllers for programmable and manual on/off control of the gas. Programmable flow control is also available.

COORDINATED MOTION MODULE

COORDINATED MOTION MODULE

Up to four motion axes can be integrated together. This allows each axis to function and coordinate together, much like the axes of a CNC milling machine, to perform welds on unique part geometries.

PRECISION BOOM

PRECISION BOOM

Both the horizontal and vertical boom motion can be upgraded with a servo motor and encoder for precise programmable control of the boom. The upgraded motion axis can then be used as an additional welding axis.

WIRELESS COMMUNICATION

WIRELESS COMMUNICATION

Includes hardware and software that allows weld programs or data to be transferred between a PC or sever and the XM® Controller wirelessly.

AVC FOR GTAW/PAW SYSTEM

AVC FOR GTAW/PAW SYSTEM

An AVC (Arc Voltage Control) Module is added to provide the weld head with automatic arc standoff. The module provides automatic height adjustments to maintain a consistent arc voltage throughout the entire weld, including automatic adjustments on multi-pass welds.

TOUCH START

TOUCH START

Arc initiated by touching the torch tip to the part for GTAW and PAW applications. This capability requires an AVC module.

BAR CODE PROGRAM SELECTION

BAR CODE PROGRAM SELECTION

Weld programs can be automatically selected by scanning a bar code associated with a specific part. This can help eliminate the incorrect program being loaded and run. Beneficial if many different parts are to be welded and operator needs to frequently switch between weld programs. Includes the bar code scanner and the necessary software to integrate with the XM® or XPro Controller.

Useful Links and Information:

Links

Contact

Please call, write, or email our headquarters in Rexburg, Idaho for more information on how we can better serve you.

355 Dividend Dr

Rexburg, ID 83440